Revista Fuentes: El Reventón Energético

Vol. 15 Nº 2 de 2017 - Jul/Dic - pp

31/47

EVIDENCES OF CDG FORMATION

AND POSSIBLE INTERPRETATIONS

OF CORE FLOOD STUDIES

Daniela Alzate López1*; Juan Manuel León2;

Fernando Cabrera3; Eduardo Manrique4 1 Universidad

Nacional de Colombia. Facultad de Minas. Calle 80 Carrera 65, Medellín,

Colombia.

2 Ecopetrol S.A. Carrera 7 Calle 32.

Bogotá D.C, Colombia.

3 Nalco Champion. Calle 100 Calle 19.

Bogotá D.C, Colombia.

4 MI3 Petroleum Engineering.

708 13th St., Golden, CO 80401, USA.

*E-mail:dalzatel@unal.edu.co

ABSTRACT

Colloidal Dispersion Gels (CDG’s) have been successfully

tested in several countries including Colombia. However, despite numerous

successful field results reported in the literature, laboratory-scale

experiments have generated controversy regarding the ability to inject CDG’s in

large volumes without reducing injectivity while also improving sweep

efficiency.

This paper summarizes the updates in microgel

technologies, especially the Linked-Polymer Solutions (LPS) that have been also

referred as CDG’s leading to misinterpretation of both systems. This brief

review will also present the main mechanisms proposed

for the formation of LPS in fluid:fluid studies and during its flow in porous

media. This study also presents for the first time

evidences of the possible mechanisms for the formation of CDG’s using a high

molecular weight (MW) partially hydrolyzed polyacrylamide (HPAM) and Aluminum

Citrate (Al(Cit)3) as a crosslinker using Dina Cretáceos Field,

Colombia, synthetic brine at room temperature (25°C).

The results generated during this study were used to re-interpret corefloods

injecting CDG in Berea and Tello Field, Colombia, core plugs at different

experimental conditions.

The main difference identified between LPS and CDG systems

is the viscosity behavior in the presence of Al(Cit)3. LPS reports a decrease in

viscosities while CDGs shows an increase in viscosities in the presence of

crosslinker. This difference is due to the use of different high MW HPAM

polymers. However, the crosslinking of the trivalent ion (Al3+) and

the negatively charged carboxylic groups of the polymer

of both microgels occurs through intra-and inter-molecular interactions leading

to different particle size or hydrodynamic diameter

distributions (HDD). The rate and type of HDD is dependent of polymer and

crosslinker concentration. These results were also compared with a CDG systems

using Chromium Acetate (Cr(Ac)3) as a crosslinker used in Loma Alta

Sur Field, Argentina. The crosslinkers used (Al3+ y Cr3+)

forming CDG suggests similar crosslinking mechanisms but

shows differences in HDD. However, the difference in the experimental

conditions of studies documented makes difficult developing a more detailed

comparison. Finally, the re-interpretation of CDG corefloods suggests that the

main operating mechanisms include viscosity effects,

adsorption, straining and log-jamming as proposed for LPS systems. However,

viscosity effects and the gradual blocking of pore channels (log-jamming) seem

to be more dominant in CDG than LPS systems. The results of this study will

contribute with the understanding of the CDG’s and also provides guidance to

improve the evaluation and research of the technology at lab scale.

Key words: CDG (Colloidal

dispersion Gels), Polyacrylamide, Hydrodynamic Diameter Distributions,

Microgels, Enhanced Oil Recovery (EOR).

Cita: Alzate, D., León, J.M., Cabrera, F. y Manrique, E. (2017). Evidences of CDG formation and possible interpretations of core flood studies. Revista Fuentes: El reventón energético, 15

(2), 31-47.

DOI: http://dx.doi.org/10.18273/revfue.v15n2-2017003

EVIDENCIAS DE LA FORMACIÓN DE CDG Y POSIBLES

INTERPRETACIONES DE PRUEBAS DE DESPLAZAMIENTO EN MUESTRAS DE NÚCLEOS

RESUMEN

La inyección de Geles de Dispersión Coloidal (CDG) ha sido evaluada

exitosamente en diferentes países incluyendo Colombia. Sin embargo y a pesar

del número de casos exitosos reportados en la literatura, estudios

experimentales han generado controversias respecto a la posibilidad de inyectar

altos volúmenes de CDG sin reducir la inyectividad y al mismo tiempo mejorar la

eficiencia de barrido en el yacimiento.

Este trabajo resume brevemente la actualidad de la tecnología de

microgeles, especialmente las Soluciones de Polímero Entrecruzadas (LPS) que

también ha sido referenciado como CDG generando confusiones en la

interpretación de ambos sistemas. Esta revisión también resume los mecanismos

propuestos para la formación de LPS basados en estudios de interacciones

fluido:fluido y durante su flujo en medios porosos. El presente estudio

documenta por primera vez las evidencias de los posibles mecanismos de la formación

de CDG utilizando una poliacrilamida parcialmente hidrolizada (HPAM) de alto

peso molecular y Citrato de Aluminio (Al(Cit)3) como entrecruzador

utilizando salmuera sintética del Campo Dina Cretáceos, Colombia, a condiciones

ambiente (25°C). Los resultados obtenidos en este estudio fueron utilizados

para re-interpretar pruebas de desplazamiento de inyección de CDG en muestras

de núcleo de Berea y del Campo Tello, Colombia, a diferentes condiciones

experimentales.

Se identifica que la principal diferencia entre el LPS y el CDG es el

comportamiento de la viscosidad en presencia de Al(Cit)3. El LPS

reporta una disminución de la viscosidad mientras que el CDG un aumento de la

misma al interactuar con este entrecruzador. Esta diferencia se basa

fundamentalmente en que estos sistemas se formulan con diferentes HPAM de alto

peso molecular. Sin embargo, se identifica que el entrecruzamiento del ion

trivalente (Al3+) y los grupos carboxílicos cargados negativamente

del polímero ocurre de manera similar para ambos sistemas a través de

interacciones intra- e inter-moleculares generando diferentes distribuciones de

tamaño de partículas o diámetros hidrodinámicos (DDH). La velocidad de reacción

y tipo de DDH resulta dependiente de las concentraciones de polímero y del

entrecruzador. Estos resultados se comparan con sistema CDG formulado con

Acetato de Cromo (Cr(Ac)3) como entrecruzador utilizado en el Campo

Loma Alta Sur, Argentina. Los entrecruzadores empleados para formar CDG (Al3+

y Cr3+) sugieren mecanismos de interacción similares pero generan

diferentes DDH. Sin embargo, las diferencias en las condiciones experimentales

de ambos estudios dificultan establecer comparaciones más detalladas. Finalmente,

la re-interpretación de pruebas de desplazamiento con CDG sugiere que los

principales mecanismos de efectos de viscosidad, adsorción, restricción y

divergencia del flujo resultan similares a los reportados para los sistemas

LPS. Sin embargo, se estima que los efectos de viscosidad y de bloqueo de

canales del medio poroso resultan más dominantes en los sistemas CDG respecto a

los LPS. Los resultados de este trabajo contribuyen con el mejor entendimiento

de los CDG y también sugiere guías para mejorar la evaluación e investigación de

la tecnología a escala de laboratorio.

Palabras Claves: CDG (Geles de Dispersión Coloidal), Poliacrilamida,

Distribuciones de Diámetros Hidrodinámicos, Microgeles, Recobro Mejorado de

Petróleo.

INTRODUCTION

porous media. CDG is one of several polymer microgel

technologies that have been proposed for in-depth Colloidal Dispersion Gels

(CDG’s) have been conformance and potentially as mobility

control method successfully tested in Argentina, China, USA, and most to

improve sweep efficiency in waterfloods. Abdulbaki, recently in Dina Cretáceos

Field, Colombia (Manrique, Huh, Sepehrnoori, Delshad & Varavei (2014)

recently et al., 2014). However, questions remain regarding reported a

literature review of different polymer the mechanisms operating during the CDG

flow in the microgel technologies (Table 1).

Table 1. Summary of polymer

microgel technologies discussed by Abdulbaki, et al., (2014).

|

Technology Gelation At

Surface Trigger In-Situ Particle Size Before Particle Size After

|

|

CDG

Preformed

CDG PPG

BrightWater

|

In-situ

Preformed

|

Polymer & crosslinker Microgel

Particle Gel

Microgel

|

Transition Pressure

Temperature

|

Swollen

microgel

Swollen

particle gel

Swollen microgel

|

nm to µm

µm to cm

0.1-1 µm

|

µm

20-200 larger

1-10 µm

|

|

pH-sensitive

|

|

|

pH

|

|

µm

|

Up to 1,000 larger

|

PPG = Preformed Particle Gels

Abdulbaki, et al. (2014) also provided a summary differentiating

polymer flooding, polymer in-situ gel flooding and polymer microgel flooding

technologies. However, this review does not differentiate Linked-

Polymer Solutions (LPS) and CDG technologies leading to

misinterpretations of both systems. Before describing the main differences of

LPS and CDG it is important provide a basic definition of these systems. LPS

and CDG are linked polymer solutions with properties like colloidal solutions.

Both systems are formed due to intra- and inter-molecular interactions of low

concentration of high MW HPAM and Al(Cit)3 as the crosslinker.

However, the viscosity and size distributions of LPS and CDG show important

differences that will be summarized in this section.

Aarra, et al. (2005) referred indistinctly in-depth

mobility control systems as LPS or CDG that are formed with low concentration

of partially hydrolyzed polyacrylamide polymer cross linked with aluminum citrate

(Al(Cit)3). However, detailed reviews of LPS studies confirmed that these systems are formed with SNF Flopaam 3630 (High MW HPAM) and Al(Cit)3 (Bjorvisk,

Hoiland, & Skauge, 2008) (Bolandtaba & Skauge, 2011) (Selle et al.,

2013) (Skauge, Hetland, Spildo, Skauge & Cipr, 2010) (Skauge, Djurhuus,

Hetland, Spildo & Skauge, 2011)generated by a crosslinking reaction between

aluminium and partially hydrolyzed Polyacrylamide (HPAM (Spildo, Skauge, Aarra

& Tweheyo, 2009) (Spildo, Skauge & Skauge,

2010). This represents the first difference with CDG systems that are formed with a different high MW HPAM commercially

available. Romero (2009) reported the effects of polymer type on the formation

of CDG in glass beads porous media.

The second difference found between these two systems is

that LPS viscosities are lower than the polymer solution at the same

concentration (Bjørsvik, Høiland & Skauge, 2008) while CDG viscosities are

higher in the presence of Al(Cit)3 compared to the polymer solution

at the same concentration (Alzate, 2016). This is also valid for CDG systems

prepared with Chromium Acetate (Diaz, et al., 2015).

Despite the differences between LPS and CDG systems, it is

important to remark that LPS studies documented in the literature reported new

insights for the re-interpretation of possible mechanisms of

CDG formation and its flow in porous media. A brief

summary of the main findings reported during research studies of LPS systems

are listed below:

LPS have properties similar to simple colloidal solution with particle size in the order of 20-150 nm (Aarra, et

al., 2005) (Bjorvisk et al., 2008) ( Bolandtaba & Skauge, 2011).

The initial crosslinking reaction is fast and takes several days to complete the reaction. The crosslinking of

trivalent ions (i.e. Al3+) and negatively

charged carboxylic groups of the polymer occurs through

intra- and inter-molecular interaction and its combination (Bjorvisk et al.,

2008) ( Spildo, et al., 2010).

LPS can propagate in porous media and increase oil recoveries (Spildo, et al., 2009) (Spildo, et al., 2010) (

Skauge, et al., 2010).

Main mechanisms reported during LPS injection include viscosity effects, adsorption, straining and log-jamming.

The microscopic diversion caused by gradual blocking of pore channels (caused

by the log-jamming mechanism) leads to diversion of

local flow mobilizing trapped oil. The effects of the

proposed mechanisms on the water relative permeability represent a balance

between the degree of blocking and the amount of produced oil ( Bolandtaba

& Skauge, 2011).

Based on the experienced gained evaluating LPS systems, this work is aimed at evaluating the CDG system injected in

Dina Cretáceos Field, Colombia. This study will use the

chemicals injected in the field and prepare the CDG in

synthetic brine to determine the effects of polymer concentration and

polymer:crosslinker ratio on the viscosity and size distribution over time. The

results of these experiments will be used to interpret

different coreflood studies developed to support the CDG injection in Dina Cretáceos and Tello Fields, Middle Magdalena

Valley, Colombia.

EXPERIMENTAL TESTS

Diaz, et al., (2015) reported for the first time the size distribution of CDG agglomerates formed during the interaction of

high molecular weight (MW) partially hydrolyzed polyacrylamide (HPAM) polymer

and Chromium Acetate (Cr(Ac)3). To further

expand the understanding of CDG systems, Alzate (2016)

developed a study evaluating the formation of CDG at lab scale using the same

HPAM and Aluminum Citrate (Al(Cit)3) as the

crosslinker (CLX). Specifically, this paper will summarize

the effects of HPAM and CLX concentration on the rheology and HDD of CDG

agglomerates formed over time.

Materials

To prepare the polymer and CDG solution synthetic water of

Dina Cretaceous Field was used. Dina synthetic water consists in NaHCO3

(0.99 g/L); NaCl (6.07 g/L); Na2SO4 (0.01 g/L); CaCl2*2H2O

(1.02 g/L); MgCl2*6H2O (0.52 g/L); BaCl2 (0.02

g/L); FeCl3*6H2O (0.03 g/L); Sr(NO3)2

(0.02 g/L); and KCl (0.10 g/L). The polymer was an HPAM (Nalco®EOR-370) with a

high MW (18-21 million Dalton) and a 30% hydrolysis. The Aluminum Citrate

(Nalco®EOR-677N) was chosen as the CLX. The CDG solutions were prepared from a

polymer stock solution of 2,000 ppm and a CLX stock solution of 1,000 ppm. The

polymer was dispersed in the synthetic water and was

mixed using a magnetic stirrer at low speed (125 RPM) for approximately 12

hours (overnight). The CLX was mixed in synthetic water to ensure its complete dissolution. It is important to mention that

all CDG systems prepared did not consider the use of

oxygen scavengers due to the low temperature (25°C) and short evaluation times

(≤ 7 days) of the experiments. Table 2

summarizes the CDG systems prepared using the stock solutions of HPAM and CLX.

Polymer concentrations and P:CLX ratio selected for this study are within the

range of the CDG system injected in Dina Cretáceos Field (Castro, et al.,

2013).

Table 2. CDG Samples.

|

Polymer

Polymer

–

Samples Concentration

Crosslinker

Ratio

(ppm)

|

Crosslinker

Concentration

( ppm )

|

|

1 Polymer

Base Line

|

400

|

|

|

2 40:1

|

400

|

10.00

|

|

3 40:1

|

600

|

15.00

|

|

4 40:1

|

200

|

5.00

|

|

5 20:1

|

400

|

20.00

|

|

6 60:1

|

400

|

6.67

|

Rheological and Hydrodynamic

Diameter Measurements

Rheological measurements were performed using a Fungilab – Alpha Series rotational

viscometer. All viscosity measurements were carried out a room temperature

25°C.

The Dynamic Light Scattering (DLS) method was used to

measure (NanoPlus – Zeta potential and Nano Particle

Analyzer) the hydrodynamic diameter of the polymer

and CDG systems. The

hydrodynamic size measured by the DLS can be defined as

“the size of a hypothetical hard sphere that diffuses

in the same way as the particle being measured” (Instruments, 2011). However,

the particles or macromolecules in solution are dynamic and non-spherical.

Therefore, the calculated diameter from the particle diffusion properties will

be an indicative of the apparent size of the dynamic particle.

The measurement principle of the DLS is based on the

Brownian motion that affects the particles dispersed in solution (Systems,

2012). The intensity and speed of this vibrational movement depend on the

temperature and the viscosity of the liquid. High temperature means more

movement. If the liquid contains a particle, that particle receives the

constant impacts of the molecules of the liquid. The vibrational velocity of

this particle also depends of its own size but the density and mass of the particle have no influence (Nelson, 1967). The Stokes-Einstein equation describes the dependence between the speed

of the movement and the size of the particles. Equation (1) presents the

Stokes-Einstein relation to calculate the particle size taking into account that the DLS method measures the diffusion coefficient and not the movement speed (Kaszuba, McKnight, Connah,

McNeil-Watson, & Nobbmann, 2008):

Where d is hydrodynamic diameter, K is the Boltzman constant, T is the temperature, µ is the viscosity of the solvent and D is the diffusion coefficient.

The DLS results are presented as diameter size

distribution respect to the differential intensity. The intensity distribution

is weighted according to the scattering intensity of each particle fraction or

particle family. This distribution may represent either a small amount of

agglomerated particles or a large particle.

As described in the equation (1), DLS measurement is

affected by the viscosity of the liquid. In the present study the viscosity

value measured at the lowest shear rate (10 rpm) was used as a reference for

measuring the hydrodynamic diameter of the CDG systems. It should be noted that

CDG or polymer solutions were not subjected to any degradation process before

the measurement of their hydrodynamic diameter. The viscosity as a function of the

shear rate and the hydrodynamic diameter of the CDG systems were evaluated at

0, 1, 3, 5, and 7 days after its preparation. All tests were performed at room

temperature.

RESULTS AND DISCUSSION

This section of the paper summarizes the results of CDG

viscosities and HDD (size) over time at different polymer concentrations and

polymer:crosslinker (P:CLX) ratios reported by Alzate (2016). The results of

this study will be used to re-interpret corefloods run

in Berea core plugs injecting CDG (using Al(Cit)3

as a crosslinker) and Dina Cretáceos Field fluids

(Castro, et al., 2013) (Manrique et al., 2014). Based

on the similarities of CDG viscosities and HDD using Al(Cit)3

(Alzate, 2016) and Cr(Ac)3 (Diaz, et al.,

2015), corefloods run in Tello core plugs injecting CDG

(using Cr(Ac)3 as a crosslinker) will be also discussed. The

re-interpretation of corefloods discussed in this paper

will also consider the evaluation of the proposed

mechanisms for the LPS systems (Bolandtaba & Skauge, 2011).

Viscosity and size distribution of CDG

system

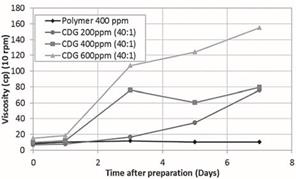

Figure 1 shows the CDG viscosity as a function of polymer

concentration (200, 400 and 600 ppm) and time for a constant P:CLX ratio of

40:1. The black line represents the viscosity of the 400 ppm polymer solution

in absence of crosslinker (Al(Cit)3). It should be noted that CDG

viscosity increases with time and polymer concentration compared to the polymer

solution at 400 ppm. As can be seen in Figure 1, the CDG system prepared with

the HPAM solution of 200 ppm and

P:CLX of 40:1 reaches a viscosity of approximately 75cp at the seventh day of evaluation while the viscosity of the

HPAM solution at 400 ppm remains constant at about 11cp. This demonstrates that

CDG can achieve higher viscosities with less polymer concentration than polymer

solutions. The reported viscosity measurements have a precision of ±0.1cp with

a repeatability of 0.2%.

The viscosity behavior showed in Figure 1 is different

from that reported in the LPS systems evaluated by Bjørsvik, et al. (2008)

showing a decrease in viscosity over time. In addition, all

the LPS systems evaluated presented a viscosity reduction immediately after the

addition of the crosslinker agent.

Figure 1. CDG

Viscosity as a function of polymer concentration and time at constant polymer:

crosslinker ratio (40:1).

Figure 2 shows the viscosity as a function of shear rate

and time for the CDG system of 400 ppm and P:CLX of 40:1. The viscosity of the

CDG systems after 1 day of its preparation is practically the same of the CDG

freshly prepared (Day 0). However, the viscosity significantly

increases after one day of interaction. CDG viscosity

continue increasing with time suggesting that the chemical interaction between

the HPAM and the crosslinker (Al(Cit)3) occurs at low reaction rates

and take place with time. Additionally, CDG systems evaluated

shows a Non-Newtonian fluid behavior, where its

viscosity depends on shear rate (Figure 2). This behavior is also similar for

the LPS systems evaluated by Bjørsvik, et al. (2008).

Figure 2. CDG

(400ppm & 40:1) viscosity as function of shear rate and time.

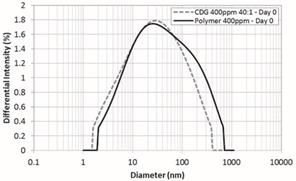

The HPAM solution of 400 ppm and the CDG system (400 ppm

and P:CLX ratio of 40:1) were selected to evaluate the HDD over time. The HDD

for the HPAM solution shows small variation over time. The HPAM solution only

develops a unimodal diameter distribution that is practically constant in the

time. The D50 is about 33.5 nm, and the particles size distribution is between

1.5 to 670 nm (Figure 3). On the contrary, the CDG systems evaluated at the

same polymer concentration shows a high variability of the HDD after 1 day of

interaction (Figure 4, Figure 5 and Figure 6). Figure 4 compares the HDD of the

HPAM solution of 400 ppm and the CDG system freshly prepared (at Day 0) at the

same polymer concentration and a P:CLX of 40:1. It can be noticed the

similarity between both distributions suggesting the slow interaction between

the polymer and the crosslinker to form the CDG agglomerates. This observation is

contrary with the fast initial crosslinking reaction reported for LPS systems.

However, both systems (CDG and LPS) requires several days to complete the

reaction (Bjorvisk, et al., 2008) (Spildo, et al., 2010).

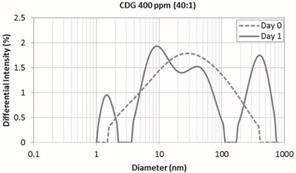

However, after the first day of the preparation the

CDG solution the HDD shows a well-defined trimodal distribution indicating particles or agglomerates with average

diameters of 1.5 nm, 20 nm and 410 nm, respectively (Figure 5). Therefore, the

range of the size distribution increased from 2-380 nm (Day 0) to 1.5- 690 nm

(Day 1). The mean peak of 20 nm (dashed red line) can represent the HPAM

molecules which probably have not started its interaction with the crosslinker.

The peak observed at 410 nm can be interpreted as the formation of larger aggregates

or larger structures than the conventional HPAM. Finally, the peak registered

at 1.5 nm suggests the formation of small molecules (or colloids)

representative of intra-molecular interactions. These results are in agreement

with the crosslinking mechanisms of LPS systems that occurs through intra- and

inter-molecular interaction and its combinations as proposed by Bjorvisk, et

al. (2008) and Spildo, et al. (2010).

Figure 6 presents the HDD of the CDG system (400 ppm and

P: CLX of 40:1) from day 0 to day 7. It can be clearly noticed the strong

presence of the 3 welldefined peaks after 3 days of

interaction compared with diameter distributions

reported for days 0 and 1. The three peaks correspond to average values of 1.1

nm, 9 nm and 150 nm after 7 days of evaluation. It is remarkable two

characteristics of these trimodal distributions: the diameter size range of the

CDG system decreases over the time and the high intensity measured for the

particles with an average diameter of 1.1 nm. The differential intensity for

the particles in the range of 1.1 nm is around 30 to 40% of the cumulative

intensity of the sample. The particles in the range of 9 nm represent about 48%

and the cumulative intensity of the largest particles (peak @ 150 nm) is about

10 to 15%. This result suggests that the intramolecular interactions are

dominant in the formation of CDG and entail the formation of small agglomerates

or colloids. However, these results needs to be further investigated due to

possible uncertainties associated to the measurements of particles below the 1

nm range.

Figure 3.

Hydrodynamic Diameter as function of time – Polymer 400 ppm.

Figure 4. Hydrodynamic

Diameter at Day 0 – Polymer 400 ppm and CDG 400 ppm – 40:1

Figure 5. Hydrodynamic

Diameter at Day 0 and 1.

CDG 400 ppm – 40:1

Figure 6. Hydrodynamic

Diameter as function of time. CDG

400 ppm – 40:1

Figure 7, Figure 8, Figure 9 and Figure 10 shows the HDD

of CDG systems as function of polymer to crosslinker (P:CLX) ratio, polymer

concentration and time. The CDG system prepared with Dina Cretáceos Field

synthetic brine, HPAM solution of 400 ppm and P:CLX of 20:1 was selected for

evaluation. This system is the closest to the CDG injected in Berea corefloods that will be discussed in the next section of this paper. This CDG system shows three regions from the first day of measurements, where their modal peaks correspond to 1.4, 30 and 450 nm, respectively (Figure 7).

This behavior differs from the observed for the CDG of 400 ppm and P:CLX of

40:1 presented in

Figure 5 exhibiting a unimodal trend at Day 0 similar to the polymer solution in absence of Al(Cit)3. This

result suggests that an increase in the concentration of the crosslinker

accelerates the formation of agglomerates. As the time of reaction progress,

three regions are completely demarcated by their intensities for the days 3 and

5 (Figure 8). These peaks are identified around 1 nm, 8

to 11 nm and 100 to 160nm, respectively. However, for the day 7 a well-defined bimodal distribution is observed with peaks at 1 nm and 24 nm (solid

blue line). The particles in the range of 1 nm correspond to 56% of the sample

analyzed. Regardless the possible uncertainties associated to the measurements

of the hydrodynamic diameters in the range or below 1 nm, these results

demonstrates the effects of higher concentrations of crosslinker on the

formation of CDG agglomerates which seems to be dominated by intra-molecular

interactions. This can be also observed in the hydrodynamic diameter of CDG’s

prepared with a HPAM solution of 400 ppm at different P:CLX ratios as shown in

Figure 9. The sample with the highest concentration of crosslinker (20:1) shows

a less dispersed distribution at day 7 of evaluation (solid red line); where

unlike samples with P:CLX of 40:1 and 60:1 the largest particles disappear.

The effect of polymer concentration at a constant P:CLX

(40:1) on the HDD distribution is depicted in Figure 10. The polymer

concentration also affects the formation of the CDG particles with time. At

early stages of interaction (day 0) the increase in polymer concentration (from

400 to 600 ppm) and the same P:CLX (40:1) accelerates the intra- and

inter-molecular interactions. This behavior was also observed with the increase

of crosslinker concentration (Figure 7). As the reaction time progress in the

CDG system with the higher polymer concentration (600 ppm) shows a different

trend of the hydrodynamic diameter than the CDG’s with lower polymer

concentrations (200 and 400 ppm) at the same P:CLX (40:1). After seven days of

interaction, the agglomerates of larger size (>100 nm) disappears for the

CDG system (solid purple line) prepared with 600 ppm of polymer (Figure 10).

This trend was also observed with the increase of the crosslinker concentration

at the same polymer concentration of 400 ppm (Figure 9).

Figure 7. Hydrodynamic

Diameter at Day 0 and 1. CDG 400 ppm – 20:1

Figure 8. Hydrodynamic

Diameter as function of time. CDG 400 ppm – 20:1

Figure 9. Hydrodynamic

Diameter as function of crosslinker concentration – Day 7.

Figure 10. Hydrodynamic

Diameter as function of polymer concentration – Day 7.

Based on the results observed evaluating the HDD of CDG

systems prepared with HPAM polymer and

|

Figure 11. Schematic

representation of a HPAM molecule and intra- and inter-molecular crosslinking

with Aluminum (crosslinker).

|

Al(Cit)3 suggests that the initial reactions

occurs through intra- and inter-molecular interactions (Figure 11). This is

consistent with the crosslinking of Al3+and negatively charged carboxylic groups of the polymer of LPS systems proposed by (Bjorvisk, et al., 2008) (Spildo, et al., 2010). The

reaction rates of CDG systems also suggest to be influenced

by the polymer and crosslinker concentrations. The

higher the concentration the faster the formation of agglomerate structures of

different sizes. Additionally, as the reaction times increase the formation of

CDG systems seems to be dominated by intra-molecular forming structures (or

colloids) of smaller size. This effect becomes more evident as the polymer and

crosslinker concentration increases. It is worth to mention that the HDD

observed for different CDG systems (Figures 6, 8 and 9) shows that the

agglomerates formed are of smaller diameter than the polymer solution in

absence of crosslinker. This smaller HDD can be consider as a factor that may

limit the importance of the microscopic diversion (log-jamming) effects as

suggested in the literature (Bolandtaba & Skauge, 2011). However, the

microscopic diversions should be interpreted as a gradual blocking due to mechanical entrapment of agglomerates (mud filter cake type) as it will be presented later in this paper.