doi:10.18273/revion.v32n1-2019007

Saccharification of Orange Bagasse Pre-treated with Calcium

Hydroxide using an enzymatic blend Diluted Hydrochloric Acid

Sacarificación de bagazo de naranja pretratado con hidroxido de calcio

usando un cóctel enzimático y acido diluido

Sacarificação de bagaço de laranja pré-tratado com hidróxido de cálcio

usando um coquetel enzimático e ácido clorídrico diluído

Danielle

Pires-Nogueira1

Paula

Rubia Ferreira-Rosa2

Araceli

Aparecida Seolatto1

Carlos

Alberto Galeano-Suarez1

Fernanda

Ferreira-Freitas1*

1Department of Chemical

Engineering, Federal University of Goias, Campus Samambaia, Goiânia, Goiás,

Brazil.

2Department of Chemical

Engineering, Federal University of São Carlos, Rodovia Washington Luis, São

Carlos, São Paulo, Brasil.

*e-mail: fernanda_ferreira_freitas@ufg.br

Cita: Pires Nogueira D, Ferreira Rosa PR, Seolatto

AA, Galeano Suarez CA, Ferreira Freitas F. Saccharification of Orange Bagasse

Pre-treated with Calcium Hydroxide using an enzymatic blend Diluted

Hydrochloric Acid. rev.ion. 2019;32(1):75-85.

Creative Commons: https://creativecommons.org/licenses/by/4.0/

https://doi.org/10.18273/revion.v32n1-2019007

Fecha recepción: 1 de noviembre de 2018

Fecha aceptación: 28 de junio de 2019

Abstract

Enzymatic and dilute acid processes were applied to study

the orange bagasse hydrolysis. The moisture, ashes, lignin, cellulose, and

hemicellulose contents, of the orange peels, were quantified. The xylanase and

cellulase enzymes activities were quantified, as well as their optimum pH and

temperatures. The pre dried orange peel biomass was pre-treated with calcium

hydroxide, at preestablished conditions. The hydrolysis followed a central

composite factorial 2³ design. The cellulase activity was 28.05x10-6

FPU (Filter Paper Units)/m3, the optimum pH was 4.8 and the

temperature was 60°C. The results for xylanase were an activity of 199.58x10-3

U/Kg, pH 5.2, and temperature 50°C. The acid hydrolysis TRS (total reducing sugars)

values varied from (9.328±0.68 mg)*10-3 TRS per Kg of biomass to

(30.15±0.31)*10-3 mg TRS per Kg biomass, the most significant factor

was the temperature and the least the time. The enzymatic hydrolysis TRS values

varied from (77.33±3.82)*10-3 mg TRS per Kg biomass to

(99.66±0.62)*10-3 mg TRS per Kg biomass, the most significant factor

was the concentration of cellulase and the least the xylanase concentration.

Keywords: Central Composite Design; Biomass; Enzymes.

Resumen

La hidrólisis del bagazo de naranja fue

realizada por medio de un proceso enzimático con celulasas y un processo

químico con ácido diluido. Las cantidades de humedad, cenizas, lignina,

celulosa y hemicelulosa fueron cuantificadas. La actividad de las enzimas fue

determinada a temperatura y pH optimo. La biomasa fue pretratada con hidróxido

de cálcio. Los experimentos de hidrólisis fueron realizados utilizando un

diseño fatorial 2³ del tipo compuesto central. La actividad de la celulasa fue

de 28,05∙10-6 FPU (Filter Paper Units)/m3, con un pH

optimo de 4,8 y una temperatura de 60°C. Asimismo los resultados para la

actividad de xilanasas obtenidos fueron de 199,58∙10-3 U/ Kg, a pH

5,2, y temperatura 50°C. Los valores de azúcares reductores totales ART de la

hidrólisis ácida variaron de (9,328 ± 0,68)*103 Kg ART

/Kg de biomasa a (30,15±0,31)∙10-3 Kg ART/ Kg de

biomasa, presentando como factor mas significativo la temperatura y como menos

significativo, el tiempo. Para el caso de la hidrólisis enzimática los valores

de ART variaron de (77,33±3,82)∙10-3 Kg ART/ Kg de biomasa a

(99,66±0,62)∙10-3 kg ART / Kg de biomasa, siendo el fator

más significativo la concentración de celulasa y el menos significativo la

concentración de xilanasa.

Palabras clave: Diseño Compuesto Central; Biomasa; Enzimas.

Resumo

A hidrólise do bagaço de laranja foi

estudada por processos enzimáticos e ácido diluído. Os teores de umidade,

cinzas, lignina, celulose e hemicelulose foram quantificados. A atividade das

enzimas foi quantificada, bem como a temperatura e o pH ótimos. A biomassa foi

pré-tratada com hidróxido de cálcio. As hidrólises seguiram um planejamento

fatorial 2³ do tipo composto central. A atividade da celulase foi 28,05∙10-6

FPU (Filter Paper Units)/m3, o pH ótimo foi 4,8 e a temperatura foi 60°C.

Os resultados da xilanase foram atividade de 199,58∙10-3 U/Kg, pH

5,2, e temperatura 50°C. Os valores de açucares redutores totais (ART) da

hidrólise ácida variaram de (9,328 ± 0,68)∙10-3 Kg ART

por Kg de biomassa a (30,15±0,31)∙10-3 Kg ART por Kg biomassa, o

fator mais significativo foi a temperatura e o menos significativo, o tempo. Os

valores de ART da hidrólise enzimática variaram de (77,33±3,82)∙10-3

Kg ART por Kg biomassa a (99,66±0,62)∙10-3 kg ART por Kg biomassa, o

fator mais significativo foi a concentração de celulase e o menos significativo

a concentração de xilanase.

Palavras chave: Planejamento Composto Central; Biomassa; Enzimas.

Introduction

Biofuels are regarded as one of the most viable options for

reduction of CO2

emissions in the transport sector [1]. Human beings have been using biofuels

since pre-historical times. Wood and vegetable oil were the most common fuels

before the 19th

century, when they started been replaced by fossil fuel. Fossil fuels that

attend over 80% of the world’s energetic needs today. However, their reserves

are limited and are being depleted at alarming rates. Global warming, high oil

prices, and new investments have been leading to the search of renewable and

sustainable fuels. In spite of that, the so called 1st generation fuels can

get in the way of feeding people. But the lignocellulosic residues generated in

industrial processes can be applied to produce 2nd generation fuels that reduce solid residues

along with solving the energy problem. Besides being promising we still have a

long way to go before this new processes are economically viable [2-5].

One of the most researched biofuels has been ethanol; it can

be produced from multiple raw materials, such as, wood, agro-industrial

residues, municipal sewage, paper industry effluents, and different grasses.

The potential use of these materials is based on their large availability and

low cost [3, 6]. The biomass productions costs in Brazil are considered the

lowest in the world, with great possibilities of promising results [7].

Orange is vastly consumed all around the world, for its

flavor as well as its medicinal and nutritional properties.

Oranges are being processed as orange juice, therefore,

generating large amounts of waste that can be easily collected from a single

site, making it a promising biomass source. About 50% of processed orange is

estimated to be waste. Brazil is the world leader of orange production, with

35% of the world’s production. The orange bagasse contains approximately 16% of

hemicellulose, 28% of cellulose and 9% lignin, showing to be a viable

alternative to produce second generation ethanol. In order to obtain ethanol

from this residues it is necessary to hydrolyze the polysaccharides into

fermentable sugars, for posterior fermentation [8-10]. The presence of lignin

in lignocellulosic biomass makes it resistant to enzymatic attack to release

sugars. Pretreatment is an important step in bioethanol production in order to

achieve maximum saccharification efficiency with high fermentable sugar yields

[11]. Pretreatment is a fundamental step for refining biofuels and biobased

products from the lignocellulosic biomass as the bioconversion of cellulose

into fermentable monosaccharides [12]. Alkaline pretreatment, a kind of

pretreatment method, possesses some desirable features. It mainly removes

lignin and can be carried out at milder conditions than several other

pretreatments, like hydrothermal pretreatments, etc. [13]. Calcium hydroxide

(Ca(OH)2) is a

possible reagent to be used for alkaline pretreatment [14]. The most impacting

unitary operation is hydrolysis, and it can be either enzymatic or acid. The

acid hydrolysis can be either dilute or concentrated. For the dilute process

high temperatures are needed, and that can generate undesired compounds. Also,

with concentrated acids there can be difficulties in the process, such as

corrosion, and hydrolysate neutralizing costs. Depending on the conditions the

acid hydrolyses can remove the lignin and part of the hemicellulose opening

pores that give access to the cellulose and spare the pre-treatment phase.

Though, but in order to break the cellulose high temperatures or acid concentrations

are needed. While, the extreme conditions can generate inhibitory co-factors,

and degrade the sugars to other compounds reducing the hydrolysis efficiency.

Before fermenting it is necessary to neutralize the hydrolysate generating

salts that can’t be separated and can either act as supplement or inhibitor to

the yeast [3, 15, 16]. Lignocellulosic biomass from vegetable waste has a great

potential for use in the production of bioethanol. Although, due to its complex

structure, it requires pretreatment to improve the yield of reducing sugars in

the hydrolysate during enzymatic hydrolysis from cellulose and hemicellulose

[17]. For the enzymatic hydrolysis it is mandatory pre-treating the biomass to

make the cellulose accessible to the enzymes. Most studies about the

lignocellulosic ethanol production involve enzymes, besides that the

hydrolysate volumes are insufficient to the following fermentation processes. Even

with the reduction in the enzymes cost in the last 20 years, they still

represent around 50% of the second generation ethanol cost, that has a very superior

cost than first generation ethanol [2,15]. The aim with the present work was to

study the feasibility of obtaining total reducing sugars from orange peels. For

this, two types of hydrolysis, dilute acid and enzymatic, were evaluated. For

acid hydrolysis, it was studied the application of milder temperatures, to reduce

energy costs as well as the generation of inhibitory compounds. For enzymatic

hydrolysis, a combination of cellulase and xylanase was studied, in order to

increase the production of reducing sugars.

Materials and methods

Biomass

The orange peels were kindly donated by a juice processing

plant (Gyn Fruit in Goiânia GO Brazil). They were then cut into smaller pieces

and kilndried at 50°C until constant weight. The dried peels were crushed in

Wiley mill, and the fines, diameter under 0.3 m, were discarded for interfering

in the pre-treatment.

Biomass Characterization

The hemicellulose and cellulose content were

determined by the method described by Browning [11]. The ash and moisture

contents were determined by the Instituto Adolfo Lutz [19] methods. The lignin

was quantified using procedure preconized by IUPAC [20].

Pre-treatment

The pre-treatment was done using calcium hydroxide, biomass

and distilled water (1:4:20 w/w/v) at 60°C for 72000s and 150 rpm [9]. After the

pre-treatment the biomass was washed with 10 times the reaction volume with

distilled water and dried at 40°C until constant weight. After drying, the

biomass was stored in plastic vials at room temperature away from the light.

Enzymatic activities

To maximize the total reducing sugars (TRS) production two

types of enzymes were used, cellulase (Sigma-Aldrich) and xylanase (Granotec) both

from Trichoderma reesei. The choice to combine this enzymes was due to

the evidence of their synergic effect on the generation of sugars [14 -17].

The cellulase activity was determined using the paper filter

method, considering the effect of pH and temperature in the activity, the

results were expressed in FPU (Filter

Paper Units)/10-6. m3 [14, 25]. The activity of the xylanase was determined using

the procedure of the University of New South Wales (Kensington, Australia),

considering the effect of temperature and pH in the activity, and the results

expressed in U/Kg [19].

Hydrolyses central composite design

Factorial planning was used in order to evaluate the dilute

acid and enzymatic hydrolyses. The tests were planned using a factorial

planning of central composite type at two levels, with three variables (2³

assays), added of three replicas in the central point, to investigate a linear

model and also 6 experiments in the axial (α) points, bringing the total to 17

experiments. [27].

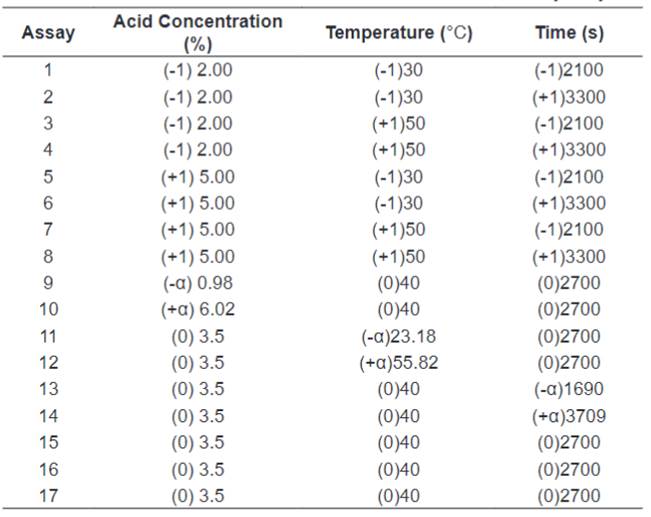

The dilute acid hydrolysis conditions for the codified and

uncodified factors (acid concentration, time and temperature) are presented in Table 1. The factors are according Dussán et al. [15]. The

hydrolysis was done using 5.10-5 m3

of chloridric acid (HCl) solution in every concentration, and what was left

after the pre-treatment of 2∙10-3 Kg of biomass in 125∙10-6 m3 Erlenmeyer flasks.

Table 1.

Codified and uncodified factors for the dilute acid hydrolysis.

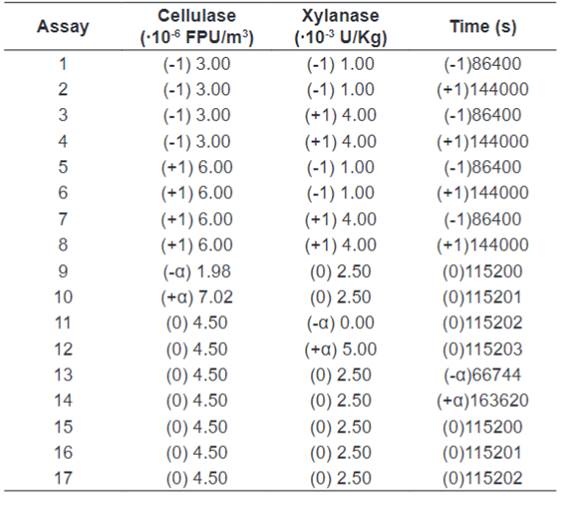

The enzymatic hydrolysis was carried out to evaluate the

impact of the enzymes concentration and time of hydrolysis. The solids

(cellulose and hemicellulose) were 1%. The buffer was sodium acetate, and the

rotation was 150 rpm. The temperature and pH were defined by the enzymatic activities

tests and constants have been kept for all experiments. Coded and non-codified

values are illustrated in the development matrix provided in Table

2. The codified alfa levels were 1.68179. In order to measure the amount of

total reducing sugars (TRS), after the hydrolyses, 1∙10-6m3 of the filtered was

measured and put in an assay tube, then 2∙10-6m3 of dinitrosalicylic acid reactant (DNS) were added. A

blank tube was done using 1∙10-6m3

of deionized water and 2∙10-6m3 of DNS. The tubes were

taken to a thermostatic bath at 95°C for 300 seconds followed by an ice bath to

stop the reaction. The volume was completed to 25∙10-6m3 and the absorbance was

read in spectrophotometer at the wave length of 540 nm [28].

Table 2.

Codified and uncodified factors for the enzymatic hydrolysis.

Results and discussion

Biomass Characterization

After being dried and milled the orange bagasse was sieved

and the particles under 0.295.103 m were discarded. The dry bagasse moisture content was

7.38%±0.03%, and the ashes content was 3.79%±0.04%. The cellulose contents were

22.9%±0.41%. The literature shows values that are similar to this [10, 29, 30].

The amount of hemicellulose was 3.39%±0.38%, value much

smaller than the researched references for orange bagasse [29-30]. The lignin

content was larger than the found for orange bagasse by other researchers

[29-30]. The composition of vegetal material may vary from different regions,

soil composition, and time of the year it was harvested [7].

Enzymatic Activities

The cellulase activity was 24.08∙10-6FPU/m3 the optimum pH was 4.8

and the optimum temperature was 60°C. For the xylanase the activity was

199.58∙10-3

U/Kg, the optimum pH was 5.2, but by a 3.4% difference to 4.8, and the optimum

temperature was 50°C. The pH of work was set at 4.8, and the temperature at

45°C.

Hydrolyses Central Composite Design

Statistical experimental design is one of the more efficient

and easier methods to arrange and interpret [31]. The results obtained in the

CCD showed that there was a good reproducibility between the central points,

statistically equal results, evidencing the quality of the repeatability of the

process. The highest response was obtained in experiment 12, performed at the

highest temperature used in the experiment (+ α). When comparing this

experiment with one of the central points there is a nearly 50% increase in the

value of the response. It is believed in the first instance that the

temperature variable has a strong influence on the release of ART after the

acid hydrolysis. It is observed a similarity of response between experiments 3

and 4, then it can be verified that when working with the lower level of acid

concentration, higher temperatures and increase of time between the lower and

upper levels the response does not change. With this, it can be inferred that

the best responses combine high temperatures and high acid concentrations, and

the time being less relevant.

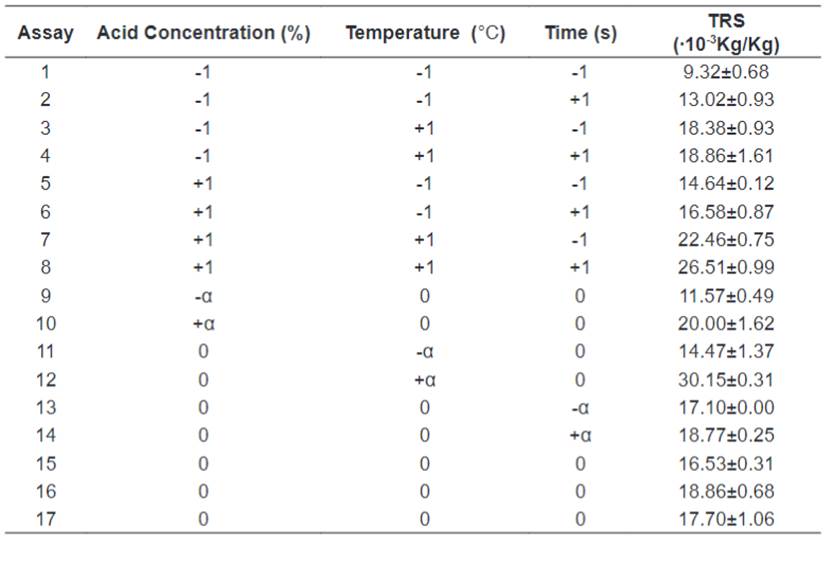

The average mass loss from the pre-treatment was 30.03%,

less than the reported by Silva et al. [9], 58.43%. For the dilute acid

hydrolysis the TRS levels varied from (9.32±0.68)∙10-3 Kg TRS per Kg of

biomass to (30.15±0.31)∙10-3

Kg TRS per Kg of biomass. All the results are presented in Table

3.

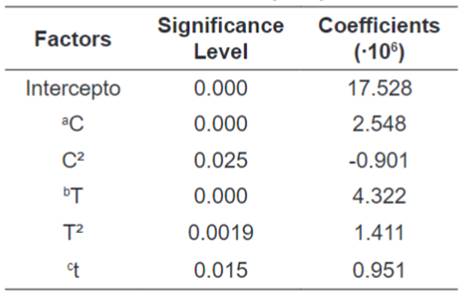

The multiple regressions of the variables were calculated

with the software Statistica ™ 7.0 and the significant terms (p≤0.1) are

presented in Table 4.

Table 3.

Amount of Total Reducing Sugars Obtained by Dilute Acid Hydrolysis of Orange

Bagasse.

Table 4.

Significant Terms of the Dilute Acid Hydrolysis Results Multiple Regression.

The reduced equation with a

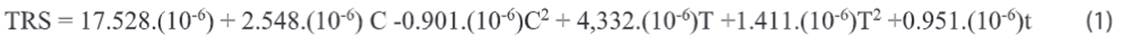

determination coefficient R² of 96% was:

Where: TRS = Total Reducing

Sugars; C = HCl Concentration; T = Temperature and t = Time

Response Surface Methodology (RSM) is successfully used for

developing efficient bioprocesses. RSM is a statistical technique used for

experiment design, model building, estimating the effect of input variables and

predicting optimum conditions [32]. From the reduced equation the response

surfaces were constructed for each pair of independent variables in function of

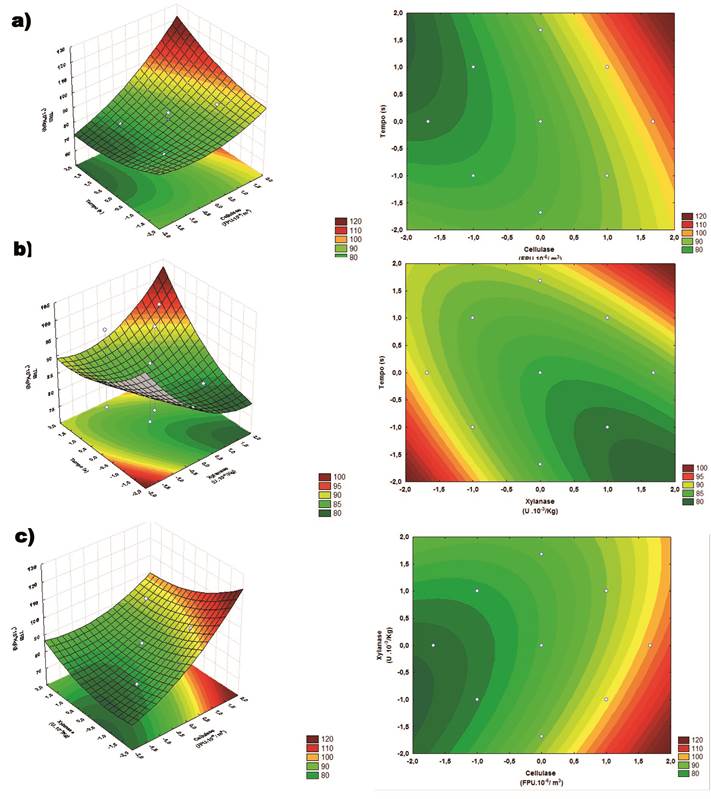

the response variable TRS (Figure 1).

The Figure 1a showed that higher temperature levels led to

higher concentrations of ART combined with HCl concentrations at their lower

levels. When the time and the concentration of HCl are compared, (Fig. 1b) it

is observed that from intermediate concentrations of acid, a greater release of

ART occurs, while there is no substantial interference of the time, which can

be verified in the value of the coefficient of the time variable in Equation 1.

Similar analysis can be verified by evaluating the relation between time and

temperature, where the higher temperature levels, caused elevations in the ART levels,

while the time was not significant for the increase of sugar concentration

(Fig. 1c).

From the data obtained it is inferred that low temperatures

of dilute acid hydrolysis lead to a partial hydrolysis of the lignocellulosic

compounds, that is, a greater liberation of reducing sugars occurs at

temperatures higher than those studied in this work. However, when comparing

with the literature, it is seen that very high temperatures favor the

degradation of the formed sugars, reducing the yield of the process [15-16,33].

The Figure shows that the temperature was the most significant

factor for the generation of TRS, with time being the least significant. The

researched literature shows that with different biomasses and higher

temperatures (135°C – 175°C) the most impacting factor tends to be the acid

concentration [15]. The difference may be due to the fact that in this work the

optimum conditions were not found, and too high temperatures may degrade the

sugars, reducing the hydrolysis’ output [33].

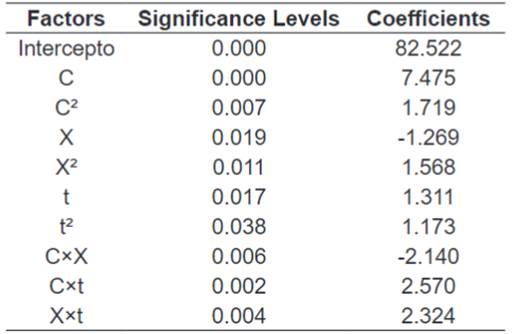

The study of enzymatic hydrolysis after pretreatment with

calcium hydroxide was performed with the enzymes cellulase and xylanase at pH

4.8 and 150 rpm at 1% solids. Through statistical planning the concentration of

TRS achieved in the enzymatic hydrolysis varied from around 75.10-6 Kg TRS per 10-3 Kg of biomass to

almost 100.10-6

Kg/ 10-3Kg

(Table 5). It is possible to observe that the results of total reducing sugars

released by the enzymatic hydrolysis were about 3 times higher than those of

the diluted acid hydrolysis. This result may indicate that, although the

optimal acid hydrolysis conditions have not been found, enzymatic hydrolysis is

more efficient for the generation of sugars from the orange bagasse.

It can be observed from Table 5 that the highest concentrations

of ART occurred in experiments 5, 6, 8 and 10, corresponding to the higher

levels of cellulase concentration (+1 and +α) and variable levels of xylanase

concentration and temperature. The lowest values of ART were in experiments 2

and 9 that have in common the lower levels of cellulase, -1 and -α

respectively. It can be observed that the concentration of xylanase practically

did not interfere in the release of ART, which can be observed when comparing

experiments 1 and 3 that with equal levels of cellulase and time and different

levels of xylanase show practically the same concentration of ART.

Figure

1.Response Surfaces and Contour Plots of the TRS (Kg.g-1): (a) HCl

Concentration (C) vs. Temperature (T);

(b) HCl Concentration

(C) vs. Time (t); (c) Temperature (T) vs. Time (t)

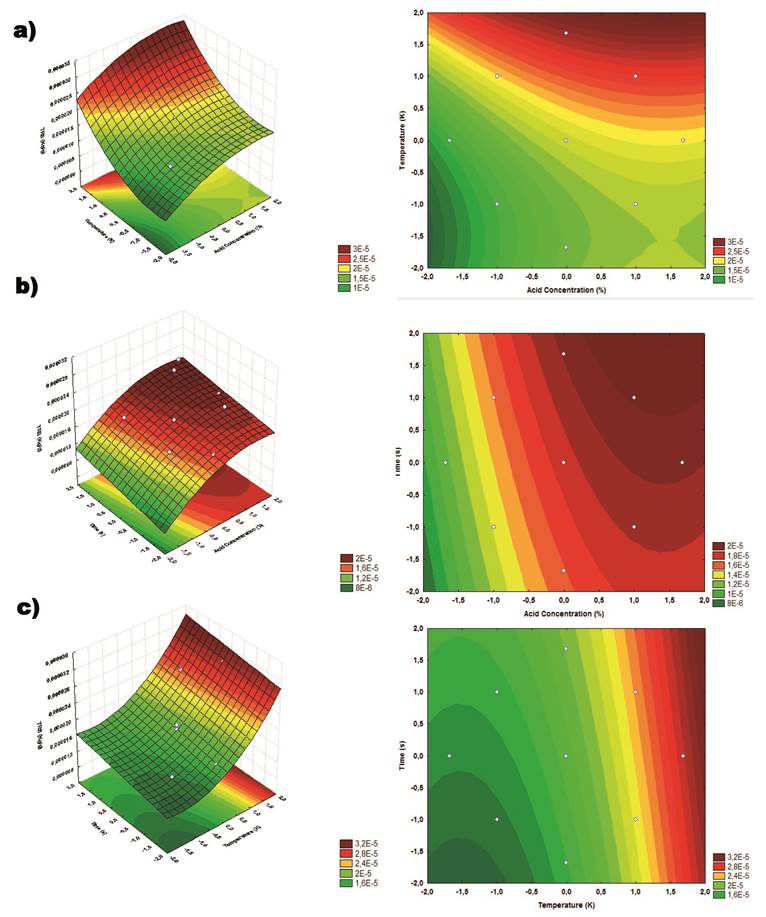

Table 5. Amount

of Total Reducing Sugars Obtained by Enzymatic Hydrolysis of Orange Bagasse.

The multiple

regressions of the variables was all the terms were significant (p≤0.1) and are

calculated with the software Statistica ™ 7.0, presented in Table

6.

Table 6.

Terms of the Dilute Acid Hydrolysis Results Multiple Regression.

The whole equation,

with a determination coefficient R² of 98.3% was:

Where: TRS = Total Reducing Sugars, C = Cellulase

Concentration, X = Xylanase Concentration t = Time.

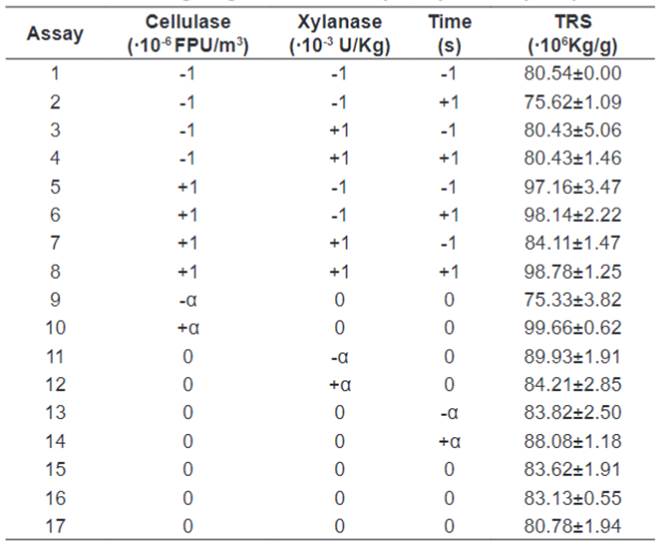

With the whole equation the response surfaces were

constructed for each pair of independent variables in function of the response

variable TRS (Figure 2).

The results demonstrate the relationship between enzyme

concentrations in the release of total reducing sugars, the highest values were

observed in the highest concentrations of cellulase (7.02∙10- 6 FPU/m3) and lower

concentrations of xylanase (0.00∙10-3 U/Kg), with the cellulase concentration being

more significant. When comparing the effect of time and cellulase concentration

on the concentration of total reducing sugars, it was observed that the higher

levels of the two variables (40 h and 7.02 ∙10-6 FPU/m3) led to higher concentrations of reducing

sugars. In the time relationship with the xylanase concentration, two maximum

regions were found for the liberation of total reducing sugars, one in the

combination of the lowest levels (0.0∙10-3 U/Kg and 18.54 h) and the other in the

combination of the highest levels (5.00∙10-3 U/Kg and 45.45 h)

The most significant factor for the generation of TRS was

the concentration of cellulose, the other factors, besides being significant,

were very much less impacting. Many authors have reported synergistic effects

on the hydrolysis of sugars by the combination of cellulase and xylanase, for

different substrates [21-24]. However, the results obtained in this work

indicate the opposite, the best results were at the highest levels of cellulase

and lowest of xylanase. When comparing the time and cellulase effect on the

generation of sugars the best results were at the combination of the highest levels

of both, which is in accordance with the literature [21-22].

Figure

2. Response Surfaces and Contour Plots of the TRS (mg g-1): (a) Cellulase

Concentration (C) vs. Time (t); (b) Xylanase Concentration (X) vs.

Time (t); (c) Cellulase Concentration (C) vs. Xylanase Concentration

(X).

Conclusions

The temperatures and acid concentrations were insufficient

to totally hydrolyze the sugars in the biomass, requiring further

investigations with higher levels of both. The enzymatic hydrolysis yielded

higher amounts of total reducing sugars (TRS) than the acid hydrolysis,

indicating it could be more advantageous for further studies. The xylanase concentration

did not impact the enzymatic hydrolysis of the orange bagasse. The studied

conditions of time and cellulase concentration were not enough to totally

hydrolyze the substrate, also requiring further studies at different

conditions.

Acknowledgements

The authors gratefully acknowledge the financial support

provided by CNPQ and FAPESP São Paulo Research Foundation.

References

1. Ohm YK, Hwang KR, Kim C, Kim JR, Lee JS. Recent

developments and key barriers to advanced biofuels: A short review. Bioresour.

Technol. 2018;257:320-33.

2. Acker RV, Leplé JC, Aerts D, Storm V, Goeminne, G,

Ivens B, et al. Improved saccharification and ethanol yield from field grown

transgenic poplar deficient in cinnamoyl-CoA reductase. PNAS.

2014;111(2):845-50.

3. Canizo JR, Cortes-Callejas ML,

Davila-Gomez

FJ, Heredia-Olea E, Perez-Carrilloa E,

SernaSaldívar SO. Release of potentially fermentable sugars during

dilute acid treatments of bermuda grass NK37 (Cynodon dactylon) for

second-generation ethanol production. J. Chem. Technol. Biotechnol. 2014;89:1941-47.

4. Guo M, Song W, Buhain J. Bioenergy and biofuels:

History, status and perspectives. Renew. Sust. Energ. Rev. 2015;42:712-25.

5. Kosinkova J, Doshi A, Maire J, Ristovski Z, Brown R,

Rainey TJ. Measuring the regional availability of biomass for biofuels and the

potential for microalgae. Renew. Sust. Energ. Rev. 2015;49:1271-85.

6. Cotana F, Cavalaglio G, Gelosia M, Nicolini A, Coccia

V, Petrozzi A. Production of bioethanol in a second generation prototype from

pinewood chips. Energ. Proc. 2014;45:42-51.

7. Silva CEF, Gois GNSB, da Silva LMO, Almeida RMRG, Abud

AKS. Citric waste saccharification under different chemical treatments. Acta

Sci. Technol. 2015;37(4):387-95.

8. Kumar CSC, Mythily R, Chandraju S. Extraction of

carbohydrate from sweet orange peels (Citrus sinensis L.) and their

identification via LC/MS & thin layer chromatographic analysis. Biosci.

Biotech. Res. Asia. 2011;8(2):709-15.

9. Silva KA, Godoy PHM, Cardoso J, Mendes TPP, Seolatto

AA, Freitas FF. Study of orange bagasse digestibility by chemical

pretreatments. Chem. Eng. Trans. 2013;35:1045-50.

10. Souza CB, Jonathan M, Saad SMI, Schols HA, Venema K.

Characterization and in vitro digestibility of by-products from Brazilian food

industry: Cassava bagasse, orange bagasse and passion fruit peel. Bioact.

Carbohydr. Dietary Fibre. 2018;16:90-9.

11. Pandiyan, K, Singh, A, Saxena, A. K, Nain, L.

Technological interventions for utilization of crop residues and weedy biomass

fors second generation bio-ethanol production. Renew. Energy. 2019;132:723-41.

12. Akhtar N, Gupta K, Goyal D, Goyal A. Recent advances in

pretreatment technologies for efficient hydrolysis of lignocellulosic biomass.

Environ. Prog.Sustain. Energy. 2016;35:489511.

13. Kim JS, Lee YY, Kim TH. A review on alkaline pretreatment

technology for bioconversion of lignocellulosic biomass. Bioresour. Technol.

2016;199:42-8.

14. Chang M, Li D, Wang W, Chen D, Zhang Y, Hu H, Ye X.

Comparison of sodium hydroxide and calcium hydroxide pretreatments on the

enzymatic hydrolysis and lignin recovery of sugarcane bagasse. Bioresour.

Technol. 2017;244:1055–58.

15. Dussán KJ, Silva DDV, Moraes EJC, Arruda PV, Felipe

MGA. Dilute-acid hydrolysis of cellulose to glucose sugarcane bagasse. Chem.

Eng. Trans. 2014;38:433-38.

16. Lenihan P, Orozco A, O’Neill E, Ahmad MNM, Rooney DW,

Walker GM. Dilute acid hydrolysis of lignocellulosic biomass. Chem. Eng. J.

2010;156:395-403.

17. Robak K, Balcerek M. Review of Second Generation

Bioethanol Production from Residual Biomass. Food Tech. & Biotech. 2018;56(2):174-87.

18. Browning BL. Methods of wood chemistry. USA, New York:

Wiley & sons; 1967.

19. Padilha P, Medeiro M, Duarte V,

Figueiredo E, Abreu P, Zenebon C. Métodos Químicos

e Físicos para Análise de Alimentos.

Digital. Brazil, São Paulo: Normas Analíticas do Instituto Adolfo Lutz; 2008.

20. Rabelo Cândida S. Avaliação e

otimização de pré-tratamentos e hidrólise enzimática do bagaço de

cana-de-açúcar para a produção de etanol de segunda geração. (Masters

Dissertation) Campinas, Brazil: Universidade Estadual de Campinas; 2010.

21. Bura R, Chandra R, Saddler J. Influence of xylan on the

enzymatic hydrolysis of steampretreated corn stover and hybrid poplar.

Biotechnol. Progr. 2009;.25(2):315-22.

22. Lin L, Yan R, Liu Y, Jiang W. In-depth investigation of

enzymatic hydrolysis of biomass wastes based on three major components:

Cellulose, hemicellulose and lignin. Bioresour. Technol. 2010;101:8217-23.

23. Selig MJ, Knoshaug EP, Adney WS, Himmel ME, Decker SR.

Synergistic enhancement of cellobiohydrolase performanceon pretreated corn

stover by addition of xylanase and esterase activities. Bioresour. Technol.

2008;99:4997-5005.

24. Xin D, Sun Z, Viikari L, Zhang J. Role of

hemicellulases in production of fermentable sugars from corn stover. Industr.

Crops Prod. 2015;74:209-17.

25. Adney B, Baker J. Measurement of Cellulase Activities.

Laboratory Analytical Procedure. Golden, USA: National Renewable energy

Laboratory. 2008.

26. Ghose TK, Bisaria VS. Measurement of hemicellulase

activities part 1: Xylanases. Great Britain. Pure Appl.

Chem.1987;59(12):173952.

27. Box GEP, Hunter JS. Multi-factor experimental designs

for exploring response surfaces. Ann. Math. Stat. 1987;28(1):195-241.

28. Miller GL. Use of dinitrosalicylic acid reagent for

determination of reducing sugar. Anal. Chem. 1959;31(3):426-28.

29. Retore M, Silva LP, Toledo GSP, Araújo IG. Efeito da fibra de coprodutos agroindustriais e sua avaliação

nutricional para coelhos. Arq. Bras. Med. Vet. Zootec. 2010;62(5):1232-40.

30. Rivas B, Torrado A, Torre P, Converti

A, Domínguez JM. Submerged citric acid fermentation on orange peel

autohydrolysate. J. Agric. Food. Chem. 2008;56:2380-7.

31. Sathendra E R, Baskar G, Praveenkumar R, Gnansounou E.

Bioethanol production from palm wood using Trichoderma reesei and Kluveromyces

marxianus. Bioresource Tech. 2019;271:345-52.

32. Baskar G, Selvakumari IAE, Aiswarya, R. Biodiesel

production from castor oil using heterogeneous Ni doped ZnO nanocatalyst.

Bioresour. Technol. 2018;250:793-8.

33. Awan TAJ A. Orange Bagasse as Biomass for 2G-Ethanol

Production. (Ph.D. Thesis) Campinas, Brazil: Universidade Estadual de Campinas;

2013.