Published 2011-01-13

How to Cite

Abstract

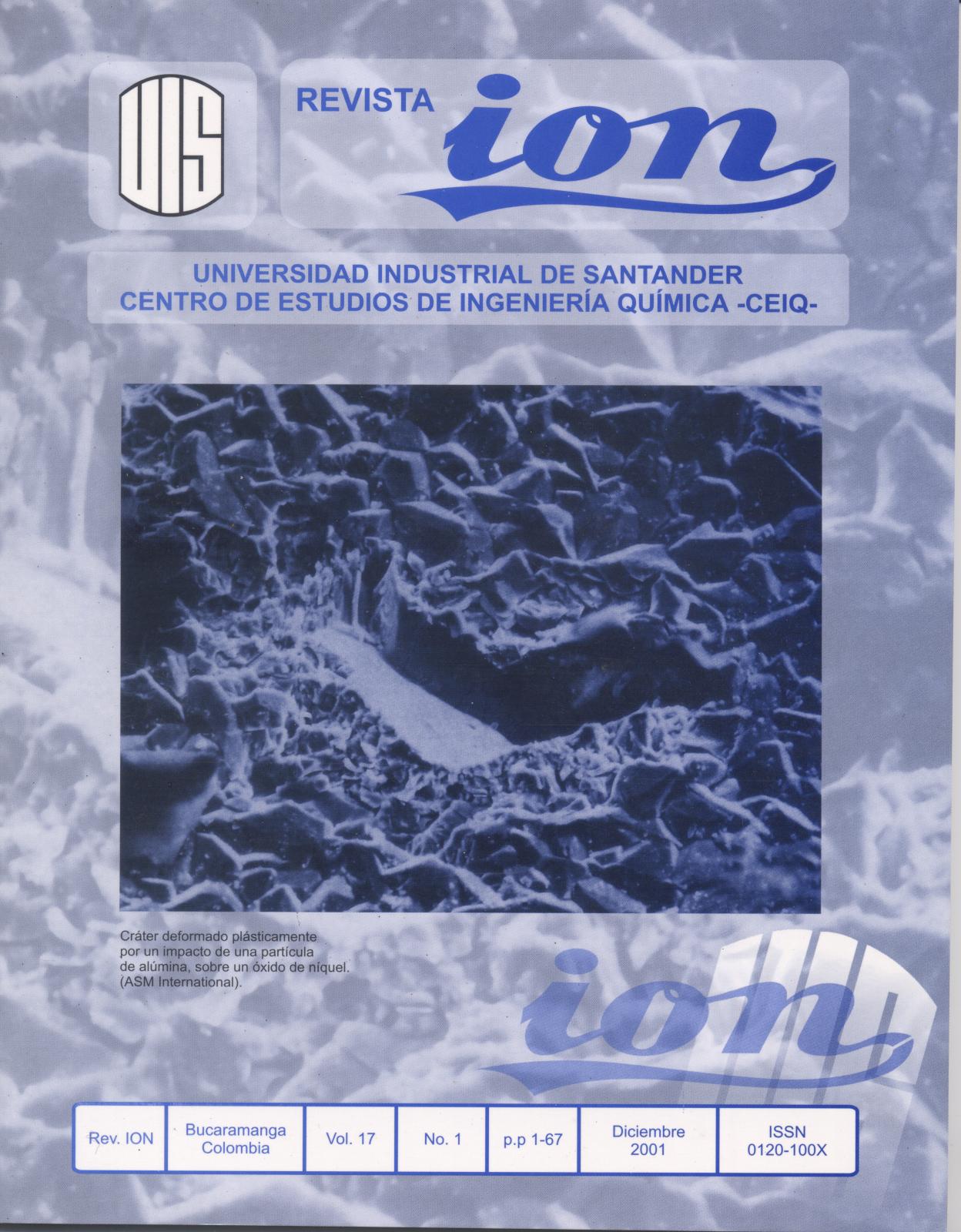

Solid particle erosion occurs on exposed components in many different types of equipment such as heat exchangers in fluidized bed combustors and pulverized coal boilers, steam-turbine blades in electric generation plants, coal gasifier internals, etc. Costs caused by erosion problems reach millions of dollars a year all over the world, therefore, it is important to know the behavior of the materials and the mechanisms of damage to choose the right material and reduce the production costs in the process.

This paper reviews the two main mechanisms of damage under erosion conditions and the basic removal of material from the surface which, contribute to catastrophic failure of the component in service.

Ni-Cr-WC coatings were tested in laboratory simulating the fluidized bed conditions, using alumina particles as erodent, to study and prove the material damage for ductile and fragile mechanisms.