Use of new propant in hydraulic fracturing of tight gas wells in colombian foothills

Published 2020-03-11

Keywords

- Tight Gas Fracturing;,

- New Proppant;,

- Deep Wells

How to Cite

Copyright (c) 2020 Revista Fuentes, el reventón energético

This work is licensed under a Creative Commons Attribution 4.0 International License.

Abstract

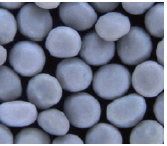

Hydraulic fracturing is a proven technique for improving both hydrocarbon productivity and water and gas injection. The Colombian foothills exhibit a special configuration of factors that increase the difficulty both during the injection and production processes, as well as in the hydraulic fracturing process due to high tectonism, structural complexity, low permeability and high depth of the reservoirs of interest.The wells located in the Colombian foothills, operated in the past by BP & Equion and currently by Ecopetrol, have been fractured in the majority to obtain economically profitable production rates. During the history of fracturing, structural complexity, high depths, high fracture gradients and high reservoir pressures have led to the usage of high strength / high density proppants such as bauxite whose physical and chemical properties complied with the technical requirements of the wells. Although this material has good properties of resistance upon closure stresses, high concentrations were normally required which, in addition to its high density, implied the use of highly viscous transport fluids requiring higher concentrations of polymer in the fluid and therefore higher levels of damage induced to formation by both, fluids and solids generated due to the ´crushing´ effect of the proppant. In recent years, it has been documented that the Pauto and Floreña formations are very sensitive to external fluids due to their low permeabilities. Based on this, this project was planned for the application of a new mixture of fluids with low polymer concentration and new proppants with better conductivity and lower density, which were tested at the laboratory level prior to field applications. This fracturing campaign was the first of its kind using fluids with the lowest concentrations in the history of the fields and is considered a benchmark for Latin America, due to its excellent results financially and production wise.

Downloads

References

Ballesteros, R. A. M., & González, F. E. C. (2016). Modelado del efecto de la movilidad del banco de finos de propante sobre las tendencias de producción en pozos hidráulicamente fracturados. Fuentes, el reventón energético, 14(2), 41-49.

Bustos, M. (2018). Selección de pozos candidatos a fracturamiento hidráulico en el campo Gustavo Galindo Velasco. Fuentes, el reventón energético, 16(1), 81-86.

Carrascal, F. A., & Contreras, Z. P. (2014). Química aplicada al control de calidad de fluidos: Éxito del fracturamiento hidráulico. Fuentes, el reventón energético, 12(2).

Carrascal, F. A., Contreras, Z. D. P. P., & Velasco, D. M. (2014). Evaluación de la eficiencia de rompedores de fluidos de fractura base agua. Fuentes: El reventón energético, 12(1), 4.

Carreño, L. D. G., Duarte, J. B. D., Hernández, E. A. G., Tarazona, D. M., & Perez, E. R. (2016). Evaluación de alternativas de costo para el suministro de propantes a un yacimiento no convencional en Colombia. Fuentes: El reventón energético, 14(1), 53-66

Jose Fernando Portela. TEC 369. Nuevas formulaciones Fluidos de control Piedemonte. 2017.

Jose Fernando Portela. TEC 358. Estimulación Hidráulica en un pozo inyector de baja permeabilidad en hueco abierto. 2017.

Kenneth G. Nolte. Reservoir Stimulation. John Wiley & Sons. 2000.

Michael J. Economides. Modern Fracturing. ET Publishing. 2007.

Ortiz, M. M., Calvete, F., Calderón, Z., Saavedra, N. F., & Corzo, R. (2010). Refracturamiento hidráulico:“una exitosa técnica de estimulación de pozos”. Fuentes, el reventón energético, 8(2).

Serrano, D. S., Gómez, C. A. P., Rueda, R. C., & Núñez, R. D. C. (2013). Implementación de propantes ultralivianos en el fracturamiento hidráulico de pozos. Fuentes: El reventón energético, 11(1), 1.