Engineering challenges and solutions in the design of an exploratory re-entry from the intermediate casing in the Colombian sub-Andean basin: case study

Published 2021-06-28

Keywords

- Re-entry,

- sidetrack,

- dogleg severity,

- curvature,

- high displacement

- long step out ...More

How to Cite

Copyright (c) 2021 Universidad Industrial de Santander

This work is licensed under a Creative Commons Attribution 4.0 International License.

Abstract

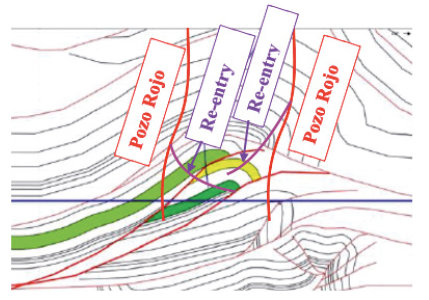

The formations and structures in Niscota, a field under exploration in the Colombian sub-Andean basin, are characterized by their high tectonic-geomechanical and sedimentological complexity as their southern neighbors, Pauto and Floreña. This means that the exploration projects (especially the drilling of wells) are expensive, delayed, and with risk structures with high impacts (evaluated in terms of time and cost). A solution to reduce costs on exploration projects is to reuse existing wells through re-access projects with significant displacements, aiming to different directions of the structure under exploration. However, these types of prospects lead to face technical, operational, and organizational challenges, for which important engineering detail and organizational maturity are required.

In this article, we present a case study where it is provided the solutions for the following challenges: Evaluation of the settling point of the diversion bucket and the associated risks; assessing the risk of string fatigue during and after milling operations; 11.75 in. siding window metal trim handling; 11.75 in. cladding window drilling parameter map; drilling in a direction orthogonal to the dip in the fault zone, and drilling in 10.625 in with curvatures greater than 4.5°/100 ft in hard and interbedded rock along with the management of geological uncertainty in areas of low seismic resolution. Additionally, the success factors are presented from the project management perspective and process safety, which allowed satisfactory earned value. Finally, the solutions proposed to the previous challenges and the efficient management of the project allowed to achieve the lowest non-productive time (NPT) of the field even compared to similar projects on similar south fields (up to 7% less) saving 1.7 million dollars.

Downloads

References

API. (1981). API Recommended practice for drill stem design and operating limits. American Petroleum Institute.

Contreras, O., Hareland, G., Husein, M., Nygaard, R., & Alsaba, M. (2014). Experimental Investigation on Wellbore Strengthening in Shales by Means of Nanoparticle-Based Drilling Fluids . https://doi.org/10.2118/170589-MS

Hoelscher, K. P., Young, S., Friedheim, J., & De Stefano, G. (2013). Nanotechnology Application in Drilling Fluids.

Lubinski, A. (1961). Maximum Permissible Dog-Legs in Rotary Boreholes. Journal of Petroleum Technology, 13(02), 175–194. https://doi.org/10.2118/1543-G-PA

Shokir, E. (2004). A novel pc program for drill string failure detection and prevention before and while drilling specially in new areas. Oil & Gas Business, 1–14.

Stelzer, C. (2007). Drillpipe Failure and its Prediction. Mining University Leoben.

Teng, X., Yang, P., Li, N., Yu, F., Jin, Y., & Chen, M. (2015). Successful HPHT Drilling Through Innovative Practices: Sharing the Subsalt HPHT Well Drilling Case in Tarim Basin . https://doi.org/SPE-172782-MS

Ugochukwu, O., Okubor, E., Aigbedion, P., & Ayodele, A. (2016). Optimizing Whipstock Sidetrack Operations . https://doi.org/10.2118/184259-MS

Vaisberg, O., Vincke, O., Perrin, G., Sarda, J. P., & Fay, J. B. (2002). Fatigue of Drillstring: State of the Art. Oil & Gas Science and Technology, 57(1), 7–37. https://doi.org/10.2516/ogst:2002002

Zhang, Y., Burhan, Y., Chen, C., Tammineni, S., Durairajan, B., Mathanagopalan, S., & Ford, R. (2013). Fully Rotating PDC Cutter Gaining Momentum: Conquering Frictional Heat in Hard/Abrasive Formations Improves Drilling Efficiency . https://doi.org/10.2118/166465-MS