Successful Application of a Water Injection Project in a Heavy Crude Reservoir with a Highly Deviated Well, its Relationship with Unfavorable Mobility and Irregular Pattern in Colombia

Published 2021-06-28

Keywords

- Waterflood,

- Heavy Oil,

- Recovery Factor,

- Selective String,

- Irregular Patterns

How to Cite

Copyright (c) 2021 Universidad industrial de Santander

This work is licensed under a Creative Commons Attribution 4.0 International License.

Abstract

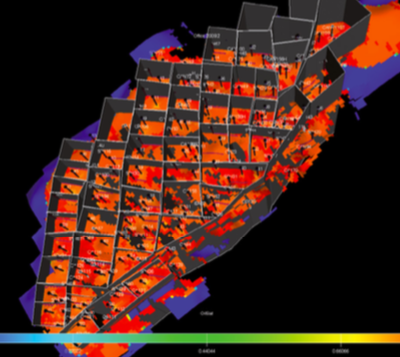

This work presents some key practices implemented in a water injection project on a heavy crude reservoir with high vertical heterogeneity and complex structure. Irregular patterns with wells located at different spaces, and a combined architecture that includes horizontal, geo-navigated, highly deviated, and vertical wells, are inherited from primary development and a viscosity ratio (μo / μw) between 200 and 600, representing a technical and operational challenge.

The success of the water injection project, under these unfavorable and complex conditions, has been the result of an effective design, implementation, control, and monitoring process. Before carrying out the design of the process, a technological screening was performed to select the most appropriate recovery process for the understudy reservoir. After that, some laboratory tests were carried out verifying fluid compatibility and critical flow rates. With this information, a 3D numerical model was built where the water injection process was simulated and become the basis for the injection pilot design. In 2015, a pilot consisting of 13 injection patterns was launched, which was the key factor in testing the process, observing its benefits, and correcting the anomalous behaviors in the expansion face. The lessons learned from this pilot were: (1) The need for a more detailed characterization of the reservoir to optimize the location of the new patterns and their volumetric predictions. Also, (2) the permanent management of vertical heterogeneity using selective strings. Finally, (3) a very rigorous process of balancing the patterns by monitoring the injection rates at the sand level, flow pressures, and production flows to minimize the water channeling and maximize oil recovery.

Nowadays, in the expansion phase, there has been a lot of progress closing 2019 with 20 employers in this project. Between 2020 and 2023, this project will be fully expanded with about 93 patterns, and in 2021 is planned to start the pilot of improved water injection (polymers) to evaluate its benefits. In this expansion process, the variables control and monitoring such as, injection/production rate and profiles, injection pressure, water quality, among others have been crucial factors to anticipate plan deviations and adjust them to better conditions that allow greater process efficiency.

The current increase in the recovery factor of some employers is 2%, and the expectation is to bring this percentage close to 6% by injecting a porous volume in 20 years. About 90MM barrels of 3P reserves associated with this project have already been incorporated. The performance results have been evaluated and compared with analytical and numerical modeling showing a better behavior than expected.

Downloads

References

Beliveau, D. Waterflooding Viscous Oil Reservoirs. (2009). SPE-113132-PA, Octubre 2009.

Compatibilidades entre Agua de Producción de la Estación Castilla y las de las Formaciones K1, K2 y T2 de Castilla (Factibilidad de Inyección de Agua de Producción). (2009). ICP, Ecopetrol.

Delamaide, E. Waterflooding Heavy Oil Reservoirs with Horizontal Wells: Field Examples from Canada. (2018). SPE-192087-MS.

Delamaide, E., et al. Pelican Lake Field: First Successful Application of Polymer Flooding In a Heavy-Oil Reservoir. (2014). SPE-165234-PA.

Depositional settings of the K2, K1 and T2 reservoir systems in Castilla Field. (2010). ARC Group.

Depositional settings of the K1Sup reservoir systems in Castilla Field. (2015). ARC Group.

Evaluación Experimental de la Inyección de Agua en Campo Castilla Formaciones K2, K1 y T2. ICP. (2012). Ecopetrol.

Jackson, R. Why Waterfloods Fail. (1968). World Oil.

Kantzas, M., Kantzas, A., et al. Heavy Oil Waterflooding: Effectsof Flow Rate and Oil Viscosity. (2007). 8th Canadian International Petroleum Conference. JCPT.

Kantzas, M., Kantzas, A. Mechanism of Heavy Oil Recovery by Low Rate. (2008). Technology Symposium 2008 Joint Conference, Alberta, Canadá.

Kantzas, M., Kantzas, A. Improved Heavy Oil Recovery by Low Rate Waterflooding. (2008). SPE International Thermal Operations and Heavy Oil, Alberta, Canadá.

Mantilla, J., Rojas, D. Guía Maestra de Inyección de Agua. (2019). GOD-G-024, VDE, Ecopetrol.

Plan de Desarrollo Castilla. (2018) Ecopetrol.