Influence of the concentrations of xanthan gum, hydroxypropyl starch and potassium chloride on the flow properties of drilling fluid formulations

Publicado 2019-06-30

Palavras-chave

- Drilling fluids,

- polymeric additives,

- rheological properties,

- operational conditions

Como Citar

Resumo

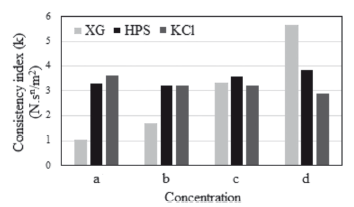

Drilling operation of oil wells involves high costs and risks. With recent discoveries of deeper reservoirs and difficult to access, there was an increase in the number of horizontal wells drilled and far-reaching, and, thereat, new challenges with operational problems. Fluids, or muds, drilling are essential to the well drilling process, confirming the need to study and find physical, rheological, and filtration properties, appropriate to the complexities in each section and the drilling stage. Optimized formulation is the one that comprises a safe operation, mitigation of operational problems, environmental protection, low cost, and high productivity. Thus, this paper offers the study of the rheological properties, and determination of filtrate volume, of the aqueous base fluid formulations, developed with polymeric additives. A high performance formulation, presenting technical-economical feasibility for drilling operations, was achieved using 0.43% m/v of viscosifier (xanthan gun), 0.57% m/v of filtrate controller (hydroxypropyl starch) and 4.57% m/v of clay swelling inhibitor (KCl).

Downloads

Referências

Albuquerque, U. R., Fagundes, F. P., Fagundes, K. R. S. Influence of bivalente cations (Ca2+ e Mg2+) in the rheological and filtration properties of aqueous drilling fluids. Revista Eletrônica de Petróleo e Gás (RUnPetro, UP), Rio Grande do Norte, 1, 9-15, 2017.

Almeida, R. D. F., Silva, W. G. A. L. Avaliação de fluidos de perfuração de base aquosa contendo poliglicóis modificados. Escola Politécnica, Universidade Federal do Rio de Janeiro, Rio de Janeiro; 2010.

API Specification 13A (Spec 13A) – American Petroleum Institute, Specification for Drilling Fluid Materials – Washington, 1993.

Ayala, D., Benítez, A., & Valencia, R. (2017). Optimización de la Tasa de Penetración mediante el análisis de las vibraciones al perforar, caso de estudio Ecuador. Revista Fuentes, 15(1), 27-40.

Ayala, D., Torres, H., Valencia, R., & Loaiza, M. (2016). Impacto del Tiempo no Productivo en operaciones de perforación y análisis de los datos mediante la prueba de Chicuadrado. Revista Fuentes, 14(2), 5-18.

Barros, A.O., Lachter, E.R., & Nascimento, R.S.V. Estabelecimento de correlações estrutura propriedades de acetais para fluidos de perfuração, 4º PDPETRO, Campinas, SP, 2007.

Borges, D. et al. Comportamento Reológico de Xantana Produzida por Xanthomonas arboricola pv pruni para Aplicação em Fluido de Perfuração de Poços de Petróleo. Polímeros: Ciência e Tecnologia, 19, 2, 160-165, 2009.

Caenn, R., Chillingar, G. V. Drilling Fluids: State of the Art. Journal of Petroleum Science and Engineering, 14, 221-230, 1996.

Caenn, R, Darley, H. C. H., Gray, G. R. Composition and properties of drilling and completion fluids. 6 ed. Gulf Professional Publishing, 2011.

Campana, D. E. A., & Tapia, R. A. V. (2017). Evaluación cualitativa de la limpieza de hoyo en pozos de alta inclinación-alto desplazamiento en la Cuenca Oriente. Revista Fuentes, 15(2), 49-56.

Diaz, S., Vendrusclo, T., Vendruscolo, S. Reologia de Xantana: uma Revisão sobre a Influência de Eletrólitos na Viscosidade de Soluções Aquosas de Gomas Xantana. Ciências Exatas e Tecnológicas, 25, 15-28, 2004.

Fernandes, J. M., Young, S. Environmentally Responsible Water- Based Drilling Fluid for HTHP Applications. AADE Fluids Conference and Exhibition. Texas, p. 6-7, 2010.

Figueira, J. N., Simão, R. A., Soares, B. G., Lucas, E. F. The influence of chemicals on asphaltenes precipitation: a comparison between atomic force microscopy and near infrared techniques. Fuentes: El Reventón Energético, 15, 7-17, 2017.

Freitas, I. C. Estudo das interações entre biopolímeros e polpas de frutas tropicais em cisalhamento estacionário e oscilatório. Universidade de Campinas: Campinas, 2002.

Garcia-ochoa, F., Santos, V. E., Casa, A., Gómez, E. Xanthan gum: production, recovery and properties. Biotechnology Advances, New York, 18, 549-579, 2000.

Guerrero-Martin, C. A., Montes-Páez, E., de Oliveira, K., Cristina, M., Campos, J., & Lucas, E. F. (2018, June). Calculating Asphaltenes Precipitation Onset Pressure by Using Cardanol as Precipitation Inhibitor: A Strategy to Increment the Oil Well Production. In SPE Trinidad and Tobago Section Energy Resources Conference. Society of Petroleum Engineers.

Huarcaya, J. C. S., Tocas, W. E. C., Ruiz, D. O., & Araque, A. D. P. B. (2019). Evaluación del uso de almidón de papa como aditivo para lodos de perforación. Revista Fuentes, 17(1), 19-28.

Ismail, A.R., Rashid, N.M., Jaafar, M.Z. Effect of nanomaterial on the rheology of drilling fluids. Journal of applied sciences, 14, 1192-1197, 2014.

Jiménez, M. J., Hernández, M. J.; Delegido, J., Casanovas, A. Flow and thixotropy of non-contaminating oil drilling fluids formulated with bentonite and sodium carboxymethyl celulose. Journal of Petroleum Science and Engineering, 56, 294-302, 2007.

Kosynkin, D.V., Ceriotti, G., Wilson, K., Lomenda, J., Scorsone, J.T.; Patel, A.D.; Friedheim, J.E.; Tour, J.M. Graphene Oxide as a High-Performance Fluid-Loss-Control Additive in Water-Based Drilling Fluids. ACS Applied Materials e Interfaces. U.S., 4, 222-227, 2012.

Loaiza, M., Ayala, D., Torres, H., & Ayala, S. (2018). Tiempo no productivo en pozos de dos secciones, caso de estudio Ecuador. Fuentes: El reventón energético, 16(1), 7-17.

Lomba, R. Fundamentos de filtração e controle de filtrado de fluidos de perfuração. Rio de Janeiro, 2010.

Lucas, E. F., Mansur, C. R. E., Spinelli, L., Queirós, Y. G. C. Polymer science applied to petroleum production. Pure and Applied Chemistry. Rio de Janeiro, 81, 473-494, 2009.

Lucas, E. F., Ferreira, L. S., Khalil, C. N. Polymers Applications in Petroleum Production, in: Encyclopedia of Polymer Science and Technology, Mark, H. F., ed., John Wiley & Sons, New York, 2015.

Lucena, D. V., Souto, C. M. R. A., Lira, H. L., Amorim, L. V. Influência de sais de potássio como inibidores de inchamento de folhelhos no desempenho de fluidos de perfuração poliméricos. Tecnol. Metal. Mater. Miner. São Paulo, 11, 355-362, 2014

Luvielmo, M.; Scamparini, R.P. Goma Xantana: produção, recuperação, propriedades e aplicação. Estudos tecnológicos, 5, 50-67, 2009.

Machado, J.C.V. Reologia e escoamento de fluidos. Rio de Janeiro, Editora Interciência, 2002.

Medina, C. A. C., Martínez, J. J. S., León, E. A., & Boada, W. M. (2013). Análisis reológico para predecir y mejorar el comportamiento hidráulico durante la perforación de un pozo. Revista Fuentes, 11(1).

Moreira, G. P. et al. Estudo comparativo entre novo emulsificante e produtos comerciais na estabilidade de fluidos de perfuração à base de éster – 4º PDPETRO – Campinas – SP, 2007.

Morris, E. R. Rheology of hydrocolloids. In: Phillips, G.O.; Wedlock, D.J.; Willians, P.A. Gums and stabilisers for the food industry. Oxford: Pergamon Press, 1984. 57-78.

Oppermann, W., Ronald, S. H. E Prud’homme, R. K., Polyelectrolyte Gelspreparation and application, Ed. ACS, Washigton, DC, cap 10, 150, 1992.

Parizad, A., Shahbazi, K.; Tanha, A. Enhancement of polymeric water-based drilling fluid properties using nanoparticles. Journal of Petroleum Science and Engineering. Iran, v.170, p. 813-828, 2018.

Pérez, R.M., Siquier, S., Ramírez, N, Muller, R.A.J.; Sáez, A.E. Non-Newtonian annular vertical flow of sand suspensions in aqueous solutions of guar gum. Journal Petroleum Science and Engineering, 44, 317-331, 2004.

Pettitt, D. J. Xanthan gum. Food Hydrocolloids, 1, 127-149, 1982

Portilla, H. E., Suárez, D. F., & Corzo, R. (2012). Metodología para la optimización de parámetros de perforación a partir de propiedades geomecánicas. Revista Fuentes, 10(2).

Sadeghalvaad, M., Sabagi, S. The effect of the TiO2/polyacrylamide nanocomposite on water-based drilling fluid properties. Powder Technology. Iran, 272, 113–119, 2015

Shiroma, P. h. Estudo do comportamento reológico de suspensão aquosa de bentonita e CMC: influência da concentração do NaCl. Ed. Ver- São Paulo, 130, 2012.

Silva, I. G. M., Lucas, E. F. Rheological properties of xanthan gum, hydroxypropyl starch, cashew gum and their binary mixtures in aqueous solutions. Macromolecular Symposia, 380, 1800070 (1-9), 2018.

Silva, I. G. M., Bertolino, L. C., Lucas, E. F. Correlation between clay type and performance of swelling inhibitors based on polyetherdiamine in aqueous fluids. Journal of Applied of Polymer Science, 136, 47661, 2019.

Vryzas, Z., Kelessidis, V. Nano-Based Drilling Fluids: A Review. Energies. Qatar, 540, 10, 1-34, 2017.

Whistler, R. L., Paschall, E. F. Starch: Chemistry and Technology, Academic Press, New York, 1965.