Review of the state of the art in transesterification technologies for biodiésel production in continuous flow and batch systems

Published 2024-11-22

Keywords

- Biodiesel,

- Renewable energy,

- Continuous flow,

- Impacts,

- Production techniques

- Reactor technologies ...More

How to Cite

Copyright (c) 2024 Michael Andres Alzate León, José Ricardo Bermúdez Santaella, Daniel Andrey Herrera Susa

This work is licensed under a Creative Commons Attribution-NoDerivatives 4.0 International License.

Abstract

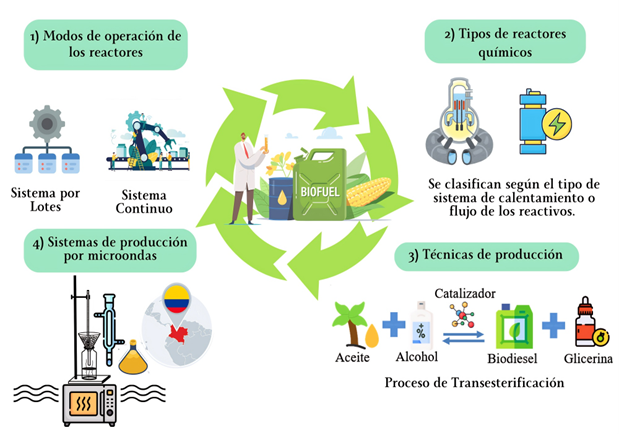

In the energy field, the search for sustainable alternatives to conventional fossil fuels has driven the development of new energy sources such as biofuels. Biodiésel in particular stands out for its ability to reduce greenhouse gas emissions and the environmental impact associated with the use and extraction of diesel. The main objective of this study is to critically review and analyze the state of the art in transesterification technologies used in biodiésel production, both in continuous flow and batch systems, with a focus on efficiency, product quality, and recent innovations in heating technologies. Likewise, in the biodiésel synthesis process, notable advances have been made in the research and development of technologies that increase production, such as heating systems and continuous flow reactors, which have become an area of growing interest due to their potential to improve the efficiency and quality of biodiésel. To this end, the state-of-the-art review was conducted based on a systematic bibliographic review, applying specific search and selection criteria for the scientific literature published between 2018 and 2023. The results obtained indicate that continuous flow systems, in combination with advanced technologies such as microwave irradiation, have shown greater potential to optimize biodiésel production compared to traditional batch methods. However, significant challenges were also identified, including high implementation costs and environmental considerations related to large-scale production.

Downloads

References

- Ashokkumar V, Flora G, Venkatkarthick R, SenthilKannan K, Kuppam C, Mary Stephy G, et al. Advanced technologies on the sustainable approaches for conversion of organic waste to valuable bioproducts: Emerging circular bioeconomy perspective. Fuel. 2022;324(PB):124313. https://doi.org/10.1016/j.fuel.2022.124313

- Brand Correa LI. Energía y bienestar: una breve historia desde la perspectiva de los límites medioambientales. Arbor. 2023;199(807):11. https://doi.org/10.3989/arbor.2023.807002

- Khatibi SR, Karimi SM, Moradi Lakeh M, Kermani M, Motevalian SA. Fossil energy price and outdoor air pollution: Predictions from a QUAIDS model. Biofuel Research Journal. 2020;7(3):1205–16. https://doi.org/10.18331/BRJ2020.7.3.4

- Aldana Urrea AV, Rodríguez Patarroyo DJ. Complementarity of energy resources for the electrical generation: a review. Ciencia e Ingeniería Neogranadina. 2019;29(2):99–114. https://doi.org/10.18359/rcin.3625.

- Njoh AJ. Renewable energy as a determinant of inter-country differentials in CO2 emissions in Africa. Renew Energy. 2021;172:1225–32. https://doi.org/10.1016/j.renene.2021.03.096

- Bautista S, Espinoza A, Narvaez P, Camargo M, Morel L. A system dynamics approach for sustainability assessment of biodiésel production in Colombia. Baseline simulation. J Clean Prod. 2019;213:1–20. https://doi.org/10.1016/j.jclepro.2018.12.111

- Li B, Haneklaus N. The role of renewable energy, fossil fuel consumption, urbanization and economic growth on CO2 emissions in China. Energy Reports. 2021;7:783–91. https://doi.org/10.1016/j.egyr.2021.09.194

- Aiello Mazzarri C, Salazar Y, Urribarrí A, Arenas Dávila E, Sánchez Fuentes J, Ysambertt F. Producción de biodiésel a partir de las grasas extraídas de la borra de café: esterificación con H2SO4 y transesterificación con KOH. Ciencia e Ingeniería Neogranadina. 2019;29(1):53–66. https://doi.org/10.18359/rcin.2899

- Villafuerte Barreto AG, Zambrano Gavilanes F, Bravo Zamora R. Evaluación Del Potencial Uso De Piñón (Jatropha Curcas L.) Para La Generación De Biocombustible. Biotempo. 2022;19(2):281–289. https://doi.org/10.31381/biotempo.v19i2.5106

- Andrade C, Corredor A, Buitrago L, Lache Muñoz A. Procesos bioquímicos utilizados Para la Producción de bioetanol, biodiésel y biogás y su estado en Colombia. América Semilleros Formación Investigativa. 2017;3(1):101–117. Disponible en: http://hdl.handle.net/20.500.11839/6444

- Zulqarnain, Mohd Yusoff MH, Ayoub M, Ramzan N, Nazir MH, Zahid I, et al. Overview of Feedstocks for Sustainable Biodiésel Production and Implementation of the Biodiésel Program in Pakistan. ACS Omega. 2021;6(29):19099–114. https://doi.org/10.1021/acsomega.1c02402

- Brahma S, Nath B, Basumatary B, Das B, Saikia P, Patir K, et al. Biodiésel production from mixed oils: A sustainable approach towards industrial biofuel production. Chemical Engineering Journal Advances. 2022;10(100284):1–31. https://doi.org/10.1016/j.ceja.2022.100284

- Medina Ramírez IE, Chávez Vela NA, Jáuregui Rincón J. Biodiésel, un combustible renovable. Investigación y Ciencia de la Universidad Autónoma de Aguascalientes. 2012;55:62–70. Disponible en: http://www.redalyc.org/articulo.oa?id=67424409008

- Kouassi KE, Abolle AA, Yao KB, Boa D, Adouby K, Drogui P, et al. Optimization of Rubber Seed Oil Transesterification to Biodiésel Using Experimental Designs and Artificial Neural Networks. Green and Sustainable Chemistry. 2018;08(01):39–61. https://doi.org/10.4236/gsc.2018.81004.

- U.S. Department of Energy’s. ASTM Biodiésel Specifications. U.S. Department of Energy’s. Disponible en: https://afdc.energy.gov/fuels/biodiésel-specifications

- Inambao F. Biodiésel Standards and Quality Testing: A Review. Journal of Harbin Engineering University [Internet]. 2023;44(10):273–95. Disponible en: https://harbinengineeringjournal.com/index.php/journal/article/view/1508

- Molero H, Moyano K, Arias Toro D. Evaluación De Las Propiedades Catalíticas De Diversos Materiales En La Producción De Biodiésel. Journal Of Science And Research. 2022;7(2):151–78. https://doi.org/10.5281/zenodo.7262003.

- Kodgire P, Sharma A, Kachhwaha SS. Biodiésel production with enhanced fuel properties via appropriation of non-edible oil mixture using conjoint ultrasound and microwave reactor: Process optimization and kinetic studies. Fuel Processing Technology. 2022;230:107206. https://doi.org/10.1016/j.fuproc.2022.107206

- Ye J, Zhu H, Yang Y, Huang K, Vijaya Raghavan GS. Dynamic analysis of a continuous-flow microwave-assisted screw propeller system for biodiésel production. Chem Eng Sci. 2019;202:146–56. https://doi.org/10.1016/j.ces.2019.03.022

- Phromphithak S, Meepowpan P, Shimpalee S, Tippayawong N. Transesterification of palm oil into biodiésel using ChOH ionic liquid in a microwave heated continuous flow reactor. Renew Energy. 2020;154:925–36. https://doi.org/10.1016/j.renene.2020.03.080

- Cavero Gonzales AM, Solis Balbuena GA. Prototipo para la Producción de Biodiesel con Micro Alga

- Chlorella vulgaris en el Desarrollo de Biotecnología Energética. Revisión Sistemática 2021 (Tesis de grado). Lima, Perú: Universidad César Vallejo; 2022.

- K Rajan K, Rajaram Narayanan M, Suresh Kumar S, Parthasarathi R, Mohanavel V. A detailed study on improving the properties and performance aspects of biodiésel. International Journal of Ambient Energy. 2022;43(1):19–53. https://doi.org/10.1080/01430750.2020.1725634

- J Ruatpuia JVL, Changmai B, Pathak A, Alghamdi LA, Kress T, Halder G, et al. Green biodiésel production from Jatropha curcas oil using a carbon-based solid acid catalyst: A process optimization study. Renew Energy. 2023;206:597–608. https://doi.org/10.1016/j.renene.2023.02.041

- Sotolongo Pérez JÁ, Rodríguez Piloto R, García Díaz A, Suárez Hernández J. Producción de biodiésel. En: Biodiésel: producción y uso. Estación Experimental de Pastos y Forrajes Indio Hatuey; 2021. p. 78.

- Rodrigues FMS, Masliy V, Silva MFC, Felgueiras AP, Carrilho RMB, Pereira MM. Catalytic multi-step continuous-flow processes for scalable transformation of eugenol into potential fragrances. Catal Today. 2023;418(February):1–12. https://doi.org/10.1016/j.cattod.2023.114055

- Dey S, Reang NM, Das PK, Deb M. A comprehensive study on prospects of economy, environment, and efficiency of palm oil biodiésel as a renewable fuel. J Clean Prod. 2021;286:124981. https://doi.org/10.1016/j.jclepro.2020.124981

- Waudby H, Zein SH. A circular economy approach for industrial scale biodiésel production from palm oil mill effluent using microwave heating: Design, simulation, techno-economic analysis and location comparison. Process Safety and Environmental Protection. 2021;148:1006–18. https://doi.org/10.1016/j.psep.2021.02.011

- Acevedo P JC, Becerra O LC, Acevedo R AZ, Posso R FR. Una revisión técnico-ambiental de la producción de biodiésel a partir de aceite de fritura residual en Colombia. Desarrollo e Innovación en Ingeniería. 2019;4:17. http://doi.org/10.5281/zenodo.3387679

- Campos Martín JM, Chica A, Domine ME, García T, Pawelec B, Pinilla JL, et al. Biocombustibles. Grupo Español Carbón [Internet]. 2020;58:1–7. https://digital.csic.es/bitstream/10261/226100/1/BoletinGEC_058-art6.pdf

- Awogbemi O, Von Kallon DV. Application of Tubular Reactor Technologies for the Acceleration of Biodiésel Production. Bioengineering. 2022;9(347):37. https://doi.org/10.3390/bioengineering9080347

- Deepak B, Mohamed Ibrahim M. Microemulsion fuel formulation from used cooking oil with carbinol as the dispersion phase. Energy Sources, Part A: Recovery, Utilization and Environmental Effects. 2023;45(2):4107–26. https://doi.org/10.1080/15567036.2023.2202624

- Kumar H, Sarma AK, Kumar P. A comprehensive review on preparation, characterization, and combustion characteristics of microemulsion based hybrid biofuels. Renewable and Sustainable Energy Reviews. 2020;117:109498. https://doi.org/10.1016/j.rser.2019.109498

- Samani BH, Behruzian M, Najafi G, Fayyazi E, Ghobadian B, Behruzian A, et al. The rotor-stator type hydrodynamic cavitation reactor approach for enhanced biodiésel fuel production. Fuel. 2021;283:118821. https://doi.org/10.1016/j.fuel.2020.118821

- Cortés Sánchez MD, Gata Montero EM, Pipió Ternero A, Rodríguez Rivas Á, Sánchez Santos JM. Biocombustibles: tipos y estrategias de producción. MoleQla: Revista de Ciencias de la Universidad Pablo de Olavide. 2019;(35):23.

- de Sousa FP, dos Reis GP, Pasa VMD. Catalytic pyrolysis of vegetable oils over NbOPO4 for SAF and green diesel production. J Anal Appl Pyrolysis. 2024;177:106314. https://doi.org/10.1016/j.jaap.2023.106314

- Cruz-Reina LJ, Flórez-Rojas JS, López GD, Herrera-Orozco I, Carazzone C, Sierra R. Obtention of fatty acids and phenolic compounds from Colombian cashew (Anacardium occidentale) nut shells using pyrolysis: towards a sustainable biodiésel production. Heliyon. 2023;9(8). https://doi.org/10.1016/j.heliyon.2023.e18632

- Manuale DL. Obtención De Biodiésel En Condiciones Supercríticas (Tesis Doctoral). Ciudad de Santafé, Argentina: Universidad Nacional de Litoral; 2011.

- Demirbaş A. Biodiésel from vegetable oils via transesterification in supercritical methanol. Energy Convers Manag. 2002;43(17):2349–56. https://doi.org/10.1016/S0196-8904(01)00170-4

- Shalfoh E, Ahmad MI, Binhweel F, Shaah MA, Senusi W, Hossain MS, et al. Fish waste oil extraction using supercritical CO2 extraction for biodiésel production: Mathematical, and kinetic modeling. Renew Energy. 2024;220:119659. https://doi.org/10.1016/j.renene.2023.119659

- Qadeer MU, Ayoub M, Komiyama M, Khan Daulatzai MU, Mukhtar A, Saqib S, et al. Review of biodiésel synthesis technologies, current trends, yield influencing factors and economical analysis of supercritical process. J. Clean. Prod. 2021;309:127388. https://doi.org/10.1016/j.jclepro.2021.127388

- Jung S, Kim M, Lin KYA, Park YK, Kwon EE. Biodiésel synthesis from bio-heavy oil through thermally induced transesterification. J Clean Prod. 2021;294. https://doi.org/10.1016/j.jclepro.2021.126347

- Mahesha CR, Rani GJ, Dattu VSNCH, Rao YKSS, Madhusudhanan J, Natrayan L, et al. Optimization of transesterification production of biodiésel from Pithecellobium dulce seed oil. Energy Reports. 2022;8:489–97. https://doi.org/10.1016/j.egyr.2022.10.228

- Lourenço VA, Nadaleti WC, Vieira BM, Li H. Investigation of ethyl biodiésel via transesterification of rice bran oil: bioenergy from residual biomass in Pelotas, Rio Grande do Sul - Brazil. Renewable and Sustainable Energy Reviews. 2021;144:111016. https://doi.org/10.1016/j.rser.2021.111016

- Ulakpa WC, Ulakpa ROE, Egwunyenga MC, Egbosiuba TC. Transesterification of non-edible oil and effects of process parameters on biodiésel yield. Cleaner Waste Systems. 2022;3:100047. https://doi.org/10.1016/j.clwas.2022.100047

- Calderon Benavides AC. Evaluación del desempeño y emisiones de mezclas biodiésel, diésel, etanol y agua en motores diésel con base en la literatura (Tesis de grado). Bogotá, Colombia: Universidad de La Salle; 2022. Disponible en: https://ciencia.lasalle.edu.co/server/api/core/bitstreams/def46a3e-be95-4ec3-8601-055e55764757/content

- Zhang J, Zhang X. The thermochemical conversion of biomass into biofuels. En: Biomass, Biopolymer-Based Materials, and Bioenergy. Elsevier; 2019. p. 327–68. https://doi.org/10.1016/B978-0-08-102426-3.00015-1

- Concepción Toledo DN, González Suárez E, López Bastida EJ, Ramos Miranda F. Gestión del conocimiento en la proyección científica de la industria química mediante diseños experimentales. Universidad y Sociedad. 2021;13(2):446–51.

- Brahma S, Nath B, Basumatary B, Das B, Saikia P, Patir K, et al. Biodiésel production from mixed oils: A sustainable approach towards industrial biofuel production. Chemical Engineering Journal Advances. 2022;10:100284. https://doi.org/10.1016/j.ceja.2022.100284

- Geng N, Zhang Y, Sun Y, Geng S. Optimization Of Biodiésel Supply Chain Produced From Waste Cooking Oil: A Case Study In China. IOP Conf Ser Earth Environ Sci. 2019;264(1):012006. https://doi.org/10.1088/1755-1315/264/1/012006

- Goyal H, Chen TY, Chen W, Vlachos DG. A review of microwave-assisted process intensified multiphase reactors. Chemical Engineering Journal. 2022;430(P4):133183. https://doi.org/10.1016/j.cej.2021.133183

- Xu C, Lan J, Ye J, Yang Y, Huang K, Zhu H. Design of continuous-flow microwave reactor based on a leaky waveguide. Chemical Engineering Journal. 2023;452(4):139690. https://doi.org/10.1016/j.cej.2022.139690

- Castillo Gonzales JP. Control de un Reactor CSRT para la Producción de Biodiésel (Tesis Doctoral). Ciudad de México, México: Tecnológico Nacional de México; 2021. Disponible en: https://rinacional.tecnm.mx/jspui/handle/TecNM/2922

- Tabatabaei M, Aghbashlo M, Dehhaghi M, Panahi HKS, Mollahosseini A, Hosseini M, et al. Reactor technologies for biodiésel production and processing: A review. Progress in Energy and Combustion Science. 2019;74:239–303. https://doi.org/10.1016/j.pecs.2019.06.001.

- Raheem I, Mohiddin MN Bin, Tan YH, Kansedo J, Mubarak NM, Abdullah MO, et al. A review on influence of reactor technologies and kinetic studies for biodiésel application. Journal of Industrial and Engineering Chemistry. 2020;91:54–68. https://doi.org/10.1016/j.jiec.2020.08.024

- Iyyaswami R, Halladi VK, Yarramreddy SR, Malur Bharathaiyengar S. Microwave-assisted batch and continuous transesterification of karanja oil: Process variables optimization and effectiveness of irradiation: Microwave-assisted transesterification of karanja oil. Biomass Convers Biorefin. 2013;3(4):305–17. https://doi.org/10.1007/s13399-013-0080-8

- Tabatabaei M, Aghbashlo M, Dehhaghi M, Panahi HKS, Mollahosseini A, Hosseini M, et al. Reactor technologies for biodiésel production and processing: A review. Prog Energy Combust Sci. septiembre de 2019;74:239–303. https://doi.org/10.1016/j.pecs.2019.06.001

- Khelafi M, Djaafri M, Kalloum S, Atelge MR, Abut S, Dahbi A, et al. Effect of stirring speeds on biodiésel yield using an innovative oscillatory reactor and conventional STR (A comparative study). Fuel. 2022;325:1248560. https://doi.org/10.1016/j.fuel.2022.124856

- Bezergianni S, Nikas V. Irradiación de microondas para la producción de biodiésel: estado del arte y desafíos futuros. Revisiones de energía renovable y sostenible. 2019;104:420–31.

- Gonçalves T dos S, Oro CED, Wancura JHC, dos Santos MSN, Junges A, Dallago RM, et al. Challenges for energy guidelines in cropbased liquid biofuels development in Brazil. Next Sustainability. 2023;2(100002):1-15. https://doi.org/10.1016/j.nxsust.2023.100002

- Goldraij A. Diseño y código técnico en la producción de biocombustibles a partir de plantas. Un análisis desde la teoría crítica de la tecnología de Andrew Feenberg. Revista iberoamericana de ciencia tecnología y sociedad. 2022;18(54):153–73. https://doi.org/10.52712/issn.1850-0013-357.

- Gónzalez JPC, Gutiérrez PEÁ, Medina MA, Zapata BYL, Guerrero GVR, Valdés LGV. Effects on biodiésel production caused by feed oil changes in a continuous stirred-tank reactor. Applied Sciences. 2020;10(3):992. https://doi.org/10.3390/app10030992

- Hernández Ferrer CL. Diseño conceptual de un proceso para la obtención de Biodiésel a partir de aceite usado de fritura (Tesis de pregrado). Valencia, España: Universidad Politécnica de Valencia; 2019. Disponible en: http://hdl.handle.net/10251/134029

- Sun W, Tao T, Lailliau M, Hansen N, Yang B, Dagaut P. Exploration of the oxidation chemistry of dimethoxymethane: Jet-stirred reactor experiments and kinetic modeling. Combust Flame. 2018;193:491–501. https://doi.org/10.1016/j.combustflame.2018.04.008

- Pérez Robert AI, Elizalde Martínez I, Monterrubio Badillo Ma del C, Mederos Nieto FS, Vázquez Medina R. Modelación matemática de un reactor de tanque agitado con catalizador disperso para la obtención de metil oleato a partir de trioleína. CIENCIA ergo sum. 2020;27(2):1–15. https://doi.org/10.30878/ces.v27n2a7

- Kouzu M, Fujimori A, Fukakusa R ta, Satomi N, Yahagi S. Continuous production of biodiésel by the CaO-catalyzed transesterification operated with continuously stirred tank reactor. Fuel Processing Technology. 2018;181:311–7. https://doi.org/10.1016/j.fuproc.2018.10.008

- Gao L, Xu W, Xiao G. Modeling of biodiésel production in a membrane reactor using solid alkali catalyst. Chemical Engineering and Processing: Process Intensification. 2017;122:122–7. https://doi.org/10.1016/j.cep.2017.09.019

- Bansod P, Kodape S, Dharaskar S, Shirsath SR. Review on membrane technology for separation of biodiésel. Materials Today: Proceedings. 2021;47(10):2415–2419. https://doi.org/10.1016/j.matpr.2021.04.482

- Bello Yaya N, Habert AC, Kronemberger F de A. Evaluation of a hollow fiber membrane contactor reactor for reactive extraction in biodiésel production. Chemical Engineering and Processing - Process Intensification. 2023;194:109574. https://doi.org/10.1016/j.cep.2023.109574

- Rozina, Ahmad M, Zafar M, Bokhari A, Akhtar MS, Alshgari RA, et al. Membrane reactor for production of biodiésel from nonedible seed oil of Trachyspermum ammi using heterogenous green nanocatalyst of manganese oxide. Chemosphere. 2023;322. https://doi.org/10.1016/j.chemosphere.2023.138078

- Wang SC, Wang XD, Teng XN, Dai JY, Dong YS, Yuan HL, et al. Fatty acid chain modification of loxenatide and its kinetics in a continuous flow microchannel reactor. Process Biochemistry. 2023;124:259–268. https://doi.org/10.1016/j.procbio.2022.12.007

- Mohd Laziz A, KuShaari KZ, Chin J, Denecke J. Quantitative analysis of hydrodynamic effect on transesterification process in T-junction microchannel reactor system. Chemical Engineering and Processing - Process Intensification. 2019;140:91–99. doi.org/10.1016/j.cep.2019.04.019

- Gholami A, Pourfayaz F, Hajinezhad A, Mohadesi M. Biodiésel production from Norouzak (Salvia leriifolia) oil using choline hydroxide catalyst in a microchannel reactor. Renew Energy. 2019;136:993–1001. https://doi.org/10.1016/j.renene.2019.01.057

- Mohd Laziz A, KuShaari KZ, Azeem B, Yusup S, Chin J, Denecke J. Rapid production of biodiésel in a microchannel reactor at room temperature by enhancement of mixing behaviour in methanol phase using volume of fluid model. Chem Eng Sci. 2020;219:115532. https://doi.org/10.1016/j.ces.2020.115532

- Yusuf NNAN, Kamarudin SK, Yaakub Z. Overview on the current trends in biodiésel production. Energy Convers Manag. 2011;52(7):2741–51. https://doi.org/10.1016/j.enconman.2010.12.004

- Omolola AO, Jideani AIO, Kapila PF. Modeling microwave drying kinetics and moisture diffusivity of mabonde banana variety. International Journal of Agricultural and Biological Engineering. 2014;7(6):107–13. https://doi.org/10.3965/j.ijabe.20140706.013

- Milano J, Ong HC, Masjuki HH, Silitonga AS, Chen WH, Kusumo F, et al. Optimization of biodiésel production by microwave irradiation-assisted transesterification for waste cooking oil-Calophyllum inophyllum oil via response surface methodology. Energy Convers Manag. 2018;158:400-15. https://doi.org/10.1016/j.enconman.2017.12.027

- Ye J, Zhang C, Zhu H. A Temperature-Control System for Continuous-Flow Microwave Heating Using a Magnetron as Microwave Source. IEEE. 2020;8:44391–9. https://doi.org/10.1109/ACCESS.2020.2978124

- Lertsathapornsuk V, Pairintra R, Aryusuk K, Krisnangkura K. Microwave assisted in continuous biodiésel production from waste frying palm oil and its performance in a 100 kW diesel generator. Fuel Processing Technology. 2008;89(12):1330–6. https://doi.org/10.1016/j.fuproc.2008.05.024

- Khedri B, Mostafaei M, Safieddin Ardebili SM. Flow-mode synthesis of biodiésel under simultaneous microwave–magnetic irradiation. Chinese Journal of Chemical Engineering. 2019;27(10):2551–2559. https://doi.org/10.1016/j.cjche.2019.03.010

- Silitonga AS, Shamsuddin AH, Mahlia TMI, Milano J, Kusumo F, Siswantoro J, et al. Biodiésel synthesis from Ceiba pentandra oil by microwave irradiation-assisted transesterification: ELM modeling and optimization. Renewable Energy. 2020;146:1278–1291. https://doi.org/10.1016/j.renene.2019.07.065

- Groisman Y, Gedanken A. Continuous flow, circulating microwave system and its application in nanoparticle fabrication and biodiésel synthesis. Journal of Physical Chemistry C. 2008;112(24):8802–8. https://doi.org/10.1021/jp801409t

- Phromphithak S, Meepowpan P, Shimpalee S, Tippayawong N. Transesterification of palm oil into biodiésel using ChOH ionic liquid in a microwave heated continuous flow reactor. Renewable Energy. 2020;154:925–936. https://doi.org/10.1016/j.renene.2020.03.080

- Mohd Ali MA, Gimbun J, Lau KL, Cheng CK, Vo DVN, Lam SS, et al. Biodiésel synthesized from waste cooking oil in a continuous microwave-assisted reactor reduced PM and NOx emissions. Environmental Research. 2020;185. https://doi.org/10.1016/j.envres.2020.109452

- Gupta J, Agarwal M, Dalai AK. An overview on the recent advancements of sustainable heterogeneous catalysts and prominent continuous reactor for biodiésel production. Journal of Industrial and Engineering Chemistry. 2020;88:58–77. https://doi.org/10.1016/j.jiec.2020.05.012

- Arpia AA, Chen WH, Lam SS, Rousset P, de Luna MDG. Sustainable biofuel and bioenergy production from biomass waste residues using microwave-assisted heating: A comprehensive review. Chemical Engineering Journal. 2021;40:126233. https://doi.org/10.1016/j.cej.2020.126233

- Falowo OA, Apanisile OE, Aladelusi AO, Adeleke AE, Oke MA, Enamhanye A, et al. Influence of nature of catalyst on biodiésel synthesis via irradiation-aided transesterification of waste cooking oil-honne seed oil blend: Modeling and optimization by Taguchi design method. Energy Conversion and Management: X. 2021.12:100119. https://doi.org/10.1016/j.ecmx.2021.100119

- Handayani PA, Athhar I, Reksono D. Optimization of Biodiésel Production from Beef Tallow Using Microwave Assisted. Journal of Advanced Research in Fluid Mechanics and Thermal Sciences. 2022;97(2):57–65. https://doi.org/10.37934/arfmts.97.2.5765

- Zhang M, Ramya G, Brindhadevi K, Alsehli M, Elfasakhany A, Xia C, et al. Microwave assisted biodiésel production from chicken feather meal oil using Bio-Nano Calcium oxide derived from chicken egg shell. Environmental Research. 2022;205:112509. https://doi.org/10.1016/j.envres.2021.112509

- Hsiao MC, Kuo JY, Hsieh SA, Hsieh PH, Hou SS. Optimized conversion of waste cooking oil to biodiésel using modified calcium oxide as catalyst via a microwave heating system. Fuel. 2020;266:117114. https://doi.org/10.1016/j.fuel.2020.117114

- Yusoff MNAM, Zulkifli NWM, Sukiman NL, Kalam MA, Masjuki HH, Syahir AZ, et al. Microwave irradiation-assisted transesterification of ternary oil mixture of waste cooking oil – Jatropha curcas – Palm oil: Optimization and characterization. Alexandria Engineering Journal. 2022;61(12):9569–82. https://doi.org/10.1016/j.aej.2022.03.040

- Gouda SP, Ngaosuwan K, Assabumrungrat S, Selvaraj M, Halder G, Rokhum SL. Microwave assisted biodiésel production using sulfonic acid-functionalized metal-organic frameworks UiO-66 as a heterogeneous catalyst. Renewable Energy. 2022;197:161–9. https://doi.org/10.1016/j.renene.2022.07.061

- Rokni K, Mostafaei M, Dehghani Soufi M, Kahrizi D. Microwave-assisted intensification of transesterification reaction for biodiésel production from camelina oil: Optimization by Box-Behnken Design. Bioresource Technology Reports. 2022;17:100928. https://doi.org/10.1016/j.biteb.2021.100928

- Sharma A, Kodgire P, Kachhwaha SS. Biodiésel production from waste cottonseed cooking oil using microwave-assisted transesterification: Optimization and kinetic modeling. Renewable and Sustainable Energy Reviews. 2019;116:109394. https://doi.org/10.1016/j.rser.2019.109394

- Asghari M, Hosseinzadeh Samani B, Ebrahimi R. Review on non-thermal plasma technology for biodiésel production: Mechanisms, reactors configuration, hybrid reactors. Energy Conversion and Management. 2022;258:115514. https://doi.org/10.1016/j.enconman.2022.115514

- Xu C, Lan J, Ye J, Yang Y, Huang K, Zhu H. Design of continuous-flow microwave reactor based on a leaky waveguide. Chemical Engineering Journal. 2023;452(P4):139690. https://doi.org/10.1016/j.cej.2022.139690

- Beccaria JA. Preparación Y Caracterización De Biodiésel A Base De Diferentes Tipos De Aceites Comestibles Y No Comestibles (Tesis de pregrado). SEDICI. Universidad Nacional De La Plata; 2012. Disponible en: http://sedici.unlp.edu.ar/handle/10915/139226

- Benti NE, Aneseyee AB, Geffe CA, Woldegiyorgis TA, Gurmesa GS, Bibiso M, et al. Biodiésel production in Ethiopia: Current status and future prospects. Sci Afr. 2023;19:e01531. https://doi.org/10.1016/j.sciaf.2022.e01531

- Velásquez Figueroa YP. Análisis sistemático de una metodología para escalado de reactores fotoquímicos heterogéneos basado en métodos matemáticos. Rev. Ing Nova. 2023;2(1):43-52. Disponible en: https://revistas.unicartagena.edu.co/index.php/ingnova/article/view/4262

- Arismendi Londoño JP, Avendaño Avendaño AJ, Parra Llanos JW, Rodríguez Ordoñez DC. Aprovechamiento de aceites vegetales usados para la obtención de biodiésel de segunda generación: una revisión. ConBRepro. 2021;1–10. Disponible en: https://aprepro.org.br/conbrepro/2021/anais/arquivos/09272021_220941_61526cf9343f5.pdf

- Reséndiz Luna JJ, Martínez Guido SI, Romero Izquierdo AG, Guitiérrez Antonio C. Producción de biodiésel en méxico: materials primas promisorias y sus rendimientos. Naturaleza y Tecnología. 2022;22–42.

- Quiros Celis MC. Estudio Analítico De Las Rutas De Conversión Para La Producción De Biodiésel A Partir De Aceite Extraído De Palma Africana (Elaeis Guineensis Jacq) (Tesis de pregrado). Pamplona, Colombia: Universidad De Pamplona; 2021. Disponible en: http://repositoriodspace.unipamplona.edu.co/jspui/handle/20.500.12744/5510