Published 2024-11-28

Keywords

- By-product,

- Dairy industry,

- Lactic acid,

- Processing scheme,

- Substrate

How to Cite

Copyright (c) 2024 Juan Carlos González Téllez, Carlos Jesús Muvdi Nova, Claudia Milena Mantilla Camacho

This work is licensed under a Creative Commons Attribution-NoDerivatives 4.0 International License.

Abstract

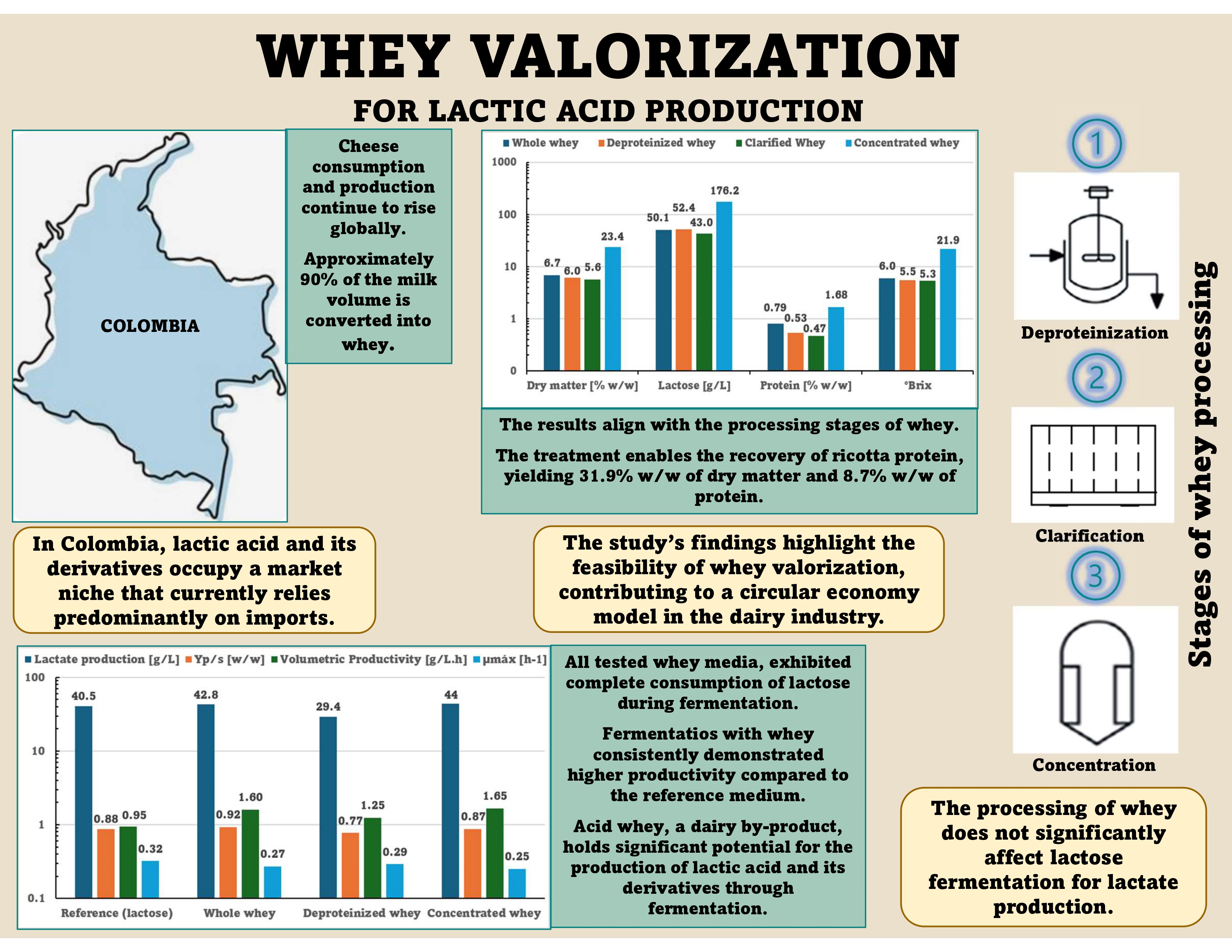

In Colombia, whey substrate has great potential to produce lactic acid and its derivatives by fermentation. Moreover, it could contribute to the development of an emerging industry that takes advantage of by-products from the dairy industry and covers a market niche that today depends mostly on imports. In this research work, a scheme of valorization of acid whey (result of the production of string cheeses), based on stages of deproteinization, clarification, and concentration, for use in lactic fermentation was studied. The results obtained in this study show a reduction of 40 % of the protein (recovered for other uses), while concentrated whey was obtained up to a Volumetric Concentration Factor (VCF) of 4, increasing the concentration of lactose and other nutrients. Fermentations were carried out with whey: whole (untreated), deproteinized and concentrated/diluted, all at a VCF of 1, to evaluate the effect of the degree of processing on the performance of the bioprocess. Fermentations with lactose reagent grade were made as references. All the evaluated media presented complete consumption of lactose, with product/substrate yields (Yp/s) between 0.77 ± 0.03 g/g and 0.92 ± 0.03 g/g for whey media, and 0.88 ± 0.04 g/g for the reference medium. In general, it was observed that fermentations with whey reached higher productivity (between 1.25 ± 0.21 and 1.65 ± 0.35 g/L/h) compared with 0.95 ± 0.35 g/L/h for the reference medium. The statistical analysis, conducted using Tukey’s test, shows that the processing stages do not significantly affect the conversion of whey to lactate.

Downloads

References

- Kötschau T, Vélez L, Echeverry J, Pulgarín J, López C, Suescún J, et al. Derivados lácteos: Contexto, tendencias y oportunidades del mercado de los derivados lácteos en Antioquia, [Documento del Clúster de Derivados lácteos de Antioquia]. Cámara de comercio de Medellín. https://onx.la/2b010

- Ganju S, Gogate PRA. Review on approaches for efficient recovery of whey proteins from dairy industry effluents. Journal of Food Engineering. 2017;215(1):84-96. https://doi.org/10.1016/j.jfoodeng.2017.07.021

- Gómez-Soto JA, Sánchez-Toro ÓJ. Production of galactooligosaccharides: Alternative for the use of whey. A review. Engineering and Development. 2019;37(1):129-157. https://doi.org/10.14482/inde.37.1.637

- Bosco F, Carletto R, Marmo L. An integrated cheese whey valorization process. Chemical Engineering Transactions. 2018;64(1):379-384. https://doi.org/10.3303/CET1864064

- Ahmad A, Banat F, Taher H. A review on the lactic acid fermentation from low-cost renewable materials: Recent developments and challenges. Environmental Technology and Innovation. 2020;20(1):101-138. https://doi.org/10.1016/j.eti.2020.101138

- Miller C, Fosmer A, Rush B, Mcmullin T, Beacom D, Suominen P. Industrial Production of Lactic Acid. Reference Module in Life Sciences. 2017;3(1):208-217. https://doi.org/10.1016/B978-0-12-809633-8.09142-1

- De Oliveira RA, Komesu A, Vaz-Rossell CE, Maciel-Filho R. Challenges and opportunities in lactic acid bioprocess design - From economic to production aspects. Biochemical Engineering Journal. 2018;133(1):219-239. https://doi.org/10.1016/j.bej.2018.03.003

- Departamento Administrativo Nacional de Estadística (DANE). Encuesta Anual Manufacturera (EAM), (2002-2017). Bogotá, Colombia. http://www.dane.gov.co/index.php/estadisticas-por-tema/industria/encuesta-anual-manufacturera-enam.

- Mora-Villalobos JA, Montero-Zamora J, Barboza N, Rojas-Garbanzo C, Usaga J, Redondo-Solano M, et al. Multi-Product Lactic Acid Bacteria Fermentations: A Review. Fermentation. 2020;6(1):23. https://doi.org/10.3390/fermentation6010023

- Coelho L, Sass DC, Avila-Neto PM, Contiero J. Evaluation of a new method for (L+) lactic acid purification, using ethyl ether. Biocatalysis and Agricultural Biotechnology. 2020;26(1):101653. https://doi.org/10.1016/j.bcab.2020.101653

- Eş I, Mousavi-Khaneghah A, Barba FJ, Saraiva JA, Santana AS, Hashemi SMB. Recent advancements in lactic acid production. A review. Food Research International. 2018;107(1):763-770. https://doi.org/10.1016/j.foodres.2018.01.001.

- Cheison S, Kulozik U. Impact of the environmental conditions and substrate pre-treatment on whey protein hydrolysis: A review. Critical Reviews in Food Science and Nutrition. 2017;57(2):418-453. https://doi.org/10.1080/10408398.2014.959115

- Vázquez-Puente F, Villegas A, Mosqueda-Frías PB. Precipitación de proteínas lactoséricas en función de la acidez, temperatura y tiempo, de suero producido en Comonfort, Guanajuato, México. Revista Venezolana de Ciencia y Tecnología de Alimentos. 2010;1(2);157-169. https://sites.google.com/site/1rvcta/v1-n2-2010/r5

- Duarte-Manchego PA, González-Téllez JC, Muvdi-Nova CJ. Evaluación de las proteínas hidrolizadas del lactosuero como fuente de nitrógeno en la fermentación láctica de la lactosa. rev. ion. 2019;32(2):15-27. https://doi.org/10.18273/revion.v32n2-2019002

- Muvdi-Nova CJ, Mora-García SA, Cáceres-Roa SA. Evaluating volume reduction of clarified acid bovine milk whey via falling film vacuum evaporation. Ciencia y Tecnología Agropecuaria (AGROSAVIA). 2021;22(1):e1241. https://doi.org/10.21930/rcta.vol22_num1_art:1241

- Tanguy G, Siddique F, Beaucher E, Santellani AC, Schuck P, Gaucheron F. Calcium phosphate precipitation during concentration by vacuum evaporation of milk ultrafiltrate and microfiltrate. LWT - Food Science and Technology. 2016;69(1):554-562. https://doi.org/10.1016/j.lwt.2016.02.023

- Petrova P, Petrov K. Lactic acid fermentation of cereals and pseudocereals: Ancient nutritional biotechnologies with modern applications. Nutrients. 2020;12(4):1118. https://doi.org/10.3390/nu12041118

- Sauer M, Russmayer H, Grabherr R, Peterbauer CK, Marx H. The efficient clade: Lactic acid bacteria for industrial chemical production. Trends in Biotechnology. 2017;35(8), 756-769. https://doi.org/10.1016/j.tibtech.2017.05.002

- Ríos-Castro A. Caracterización del proceso de obtención y separación de ácido láctico a partir de lactosuero usando tecnología de membranas (Master’s Thesis). Querétaro, México: Universidad Autónoma de Querétaro; 2011. Repository http://ri-ng.uaq.mx/handle/123456789/607

- García CM, Arrázola W, Villalba M. Production of lactic acid from whey supplemented using Lactobacillus casei. Biotechnology in the Agricultural and Agro-industrial Sector. 2013;11(1):136-143.

- Mccabe W, Smith JC, Harriott P. Unitary operations in chemical engineering. 7 ed. España: McGraw-Hill Interamericana de España; 2007.

- AOAC. Official Method 990.19, Dry Matter. In: Official Methods of Analysis. 17th ed. Gaithersburg, MD: AOAC International; 2000.

- AOAC. Official Method 991.20, Protein. In: Official Methods of Analysis. 17th ed. Gaithersburg, MD: AOAC International; 2000.

- AOAC. Official Method 2000, Fat. In: Official Methods of Analysis. 17th ed. Gaithersburg, MD: AOAC International; 2000.

- AOAC. Official Method 923.03, Ash. In: Official Methods of Analysis. 17th ed. Gaithersburg, MD: AOAC International; 2000.

- Nielsen EN, Merkel A, Yazdi SR, Ahrné L. The effect of acid whey composition on the removal of calcium and lactate during electrodialysis. International Dairy Journal. 2021;117(1):e104985. https://doi.org/10.1016/j.idairyj.2021.104985

- Riera-Rodríguez FA, González P, Muro C. Whey cheese: Membrane technology to increase yields. Journal of Dairy Research. 2016;83(1):96-103. https://doi.org/10.1017/S0022029915000679

- Shuler M, Kargi F. Bioprocess Engineering: Basic Concepts. 2 ed. USA: Prentice Hall; 2000.

- Büyükkileci A, Harsa S. Batch production of L(+) lactic acid from whey by Lactobacillus casei (NRRL B-441). Journal of Chemical Technology and Biotechnology. 2004;79(9):1036-1040. https://doi.org/10.1002/jctb.1094