Effect of the mixture of corrosion and scaling inhibitors on protection against corrosion of carbon steel

Published 2015-12-03

Keywords

- Corrosion,

- Scaling,

- Inhibitors,

- Oil and gas production,

- Offshore

- Presalt,

- Brazil ...More

How to Cite

Abstract

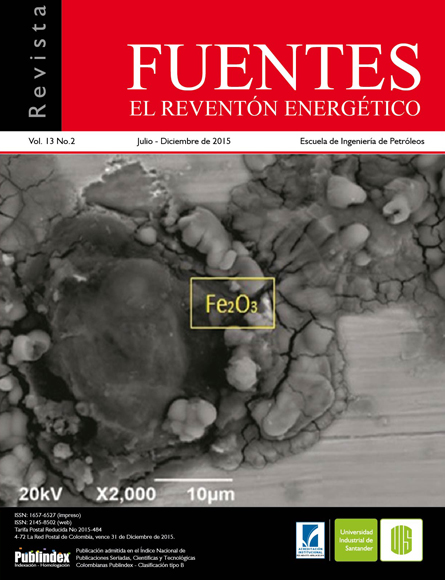

The advances of the new technologies in order to explore and produce oil and gas in deep and ultra-deep water is followed with challenges related to corrosion and scaling issues in production and injection wells. in the same way, scaling control in production wells due to carbonate deposition is one of the innumerous challenges of the Brazilian Pre salt. scaling leads to fl ow restriction and erosion problems in addition corrosion problems which may lead to a production decrease. One of the procedures adopted for removal and scaling inhibition is using inorganic (HCl) or organic (acetic acid) acids, however, the use of these ones is done by the presence of corrosion inhibitors in high level concentration which have high costs. Chelates, such as EDTA, can be used as alternatives in oil and gas wells both in stimulation operations and for the prevention and removal of scales. This work aims to study the effect of the mixture of two kinds of compounds (corrosion and scaling inhibitors) on carbon steel protection by mass loss measurements, electrochemical tests and qualitative scaling test. it was verifi ed an increasing of the corrosion rate of carbon steel by the presence of EDTA, which was reduced by the addition of both anticorrosive and antiscaling compounds.

Downloads

References

2. Moghadasi J. et al. “Scale Deposits in Porous Media and Their Removal By EDTA Injection”. Proceedings of 7th International Conference on Heat Exchanger Fouling and Cleaning -Challenges and Opportunities, Engineering Conferences International, Tomar, Portugal, July, 2007

3. Crabtree M. Fighting.“Scale: Removal and Prevention”.Oilfield Review Autumn 1999. http:// www.slb.com/~/media/Files/resources/oilfield_ review/ors99/aut99fighting.pdf

4. Portier S.A., Vuataz F-D. “Review on Chemical Stimulation Techniques in Oil Industry and Applications to Geothermal Systems”. A technical report prepared for the EC-financed co-ordination projtec ENGINE (Enhanced Geothermal Innovative Network for Europe). Work Package 4: Drilling, stimulation and reservoir assessment. CREGE-Centre for Geothermal Research Neuchatel, November, 2007.

5. C.N. Fredd; H. Scott Fogler:“Alternative Stimulation Fluids and Their Impact on Carbonate Acidizing”SPE Journal, March 1998.

6. Arai, A.; Duarte, L.R andMussumeci, A: “Estudo da Formação de Incrustações Carbonáticas”. Tesis de Pregrado. Universidade Federal do Rio de Janeiro, 2010.

7. Palmer J.W., Boden P.J. “Corrosionof Steel in EDTA”. British Corrosion Journal. V. 27, N. 4 p. 305-309

8. Azevedo, C. R. F. ; Rodrigues, D. ; Ferrari, J.V. “Environmentally Assisted Fracture of Sintered Nickel Cartridges”. Engineering Failure Analysis, v. 14, p. 1266-1279, 2007

9. Freed C.N., Fogler S. “Alternative Stimulation Fluids and Their Impact on Carbonate Acidizing”. SPE Journal. March 2998, p. 34

10.Zor S., Özkazanç H., Bingul M. “Effect of Ethylene Diaminetetraacetic Acid on the Corrosion of Aluminum in Chloride Solutions”. Materials Science. v. 44, n.6, p. 850-856

11.Panossian, Z. “Corrosão e proteção contra corrosão em equipamentos e estruturas metálicas”. São Paulo: Instituto de Pesquisas Tecnológicas (IPT), 1993.

12.V. Tantayakoma,b, T. Sreethawong b, H. Scott Fogler a,∗, F.F. de Moraes c, S. Chavadej. “Scale inhibition study by turbidity measurement”Journal of Colloid and Interface Science 284 (2005) 57–65.

13.J. W. PalmerP. J. Boden. “Corrosion of steel in EDTA” British CorrosionJournal1992; 27(4), 305-309.

14.E. Kusmierek; E.Chrzescijanska.“Tannic Acid as corrosion inhibitor for metals and alloys. Materials and Corrosion” 2015,66n2

15.Godec-Fuchs R; Povlovic M.G.; Tomic M.V. “The inhibitive effect of Vitamin-C on the Corrosive Performance of Steel in HCl solutions”.Int. J. ElectrovchemSci, 8 (2013) 1511-1519