Evaluación experimental de la eficiencia de un colector solar de tubos evacuados sin y con tubo de calor

Publicado 2019-06-30

Palabras clave

- Energía Solar,

- Sistema de Calentamiento de Agua,

- Colector Solar de Tubos Evacuados,

- Tubo de Calor,

- Eficiencia

Cómo citar

Esta obra está bajo una licencia internacional Creative Commons Atribución 4.0.

Resumen

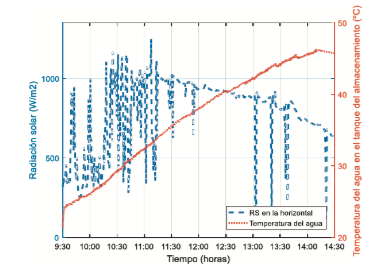

En la presente investigación se evaluó experimentalmente la eficiencia de un colector solar de tubos evacuados (CSTE) sin y con tubo de calor en días soleados, parcialmente nublados y nublados. En total se realizaron 46 experimentaciones durante 23 días: marzo a junio del 2017, con dos CSTE sin y con tubo de calor de 100 y 120 L, respectivamente. La radiación solar en la superficie horizontal y temperatura del agua en la salida del tanque de almacenamiento se registraron durante 5 horas (9:30 am a 2:30 pm) en intervalos de 30 y 10 s, respectivamente. Para las representaciones y estimaciones de la eficiencia se utilizó el lenguaje de programación Matlab.

Los resultados muestran una ligera superioridad de eficiencia del CSTE con tubo de calor (60,35%, 61,21% y 66,08%) comparado al sin tubo de calor (57,17%, 57,29% y 59,56%), medidos en días soleados, parcialmente nublados y nublados, respectivamente. Y se observa que en el CSTE con tubo de calor es mayor el incremento de la eficiencia en días nublados por las menores pérdidas de calor debido a un menor incremento de la temperatura, generando un mayor aprovechamiento de la energía solar incidente. El análisis de varianza indicó que la condición de la radiación solar y tubo de calor del CSTE no influyen significativamente en la eficiencia energética de este colector solar.

De acuerdo a la condición de radiación solar (días soleados, parcialmente nublados y nublados), el CSTE con tubo de calor presentó una mayor eficiencia de 3,20 %, 3,92 % y 6,52%, respecto al CSTE sin tubo de calor.

Descargas

Referencias

2. Amaris, J. M., Manrique, D. A., & Jaramillo, J. E. (2015). Biocombustibles líquidos en Colombia y su impacto en motores de combustión interna. Una revisión. Revista Fuentes, 13(2), 23-34.

3. Ayala, F. E. B., Gómez, J. Q., & León, E. A. (2011). Estudio de factibilidad del uso del biodiesel como fase contínua en lodos de perforación de emulsión inversa. Revista Fuentes, 9(1).

4. Budihardjo, I., & Morrison, G. (2009). Performance of water-in-glass evacuated tube solar water heaters. Solar Energy, 83(1), 49–56. doi:10.1016/j.solener.2008.06.010

5. Conicet, I. (2009). Colectores solares para agua caliente. UNSA, Argentina.

6. Duffie, J., & Beckman, W. (2013). Solar engineering of thermal processes (Cuarta ed.). New Jersey, Canada: Wiley.

7. Forero, L. E. P., Castro, Z. S., Bernal, H. R. G., & Ávila, H. S. R. (2012). Hornillas paneleras Ward-Cimpa: validación de los modelos matemáticos de diseño Corpoica-UIS. Revista Fuentes, 10(2).

8. Hamed, M., Fellah, A., & Ben Brahim, A. (2014). Parametric sensitivity studies on the performance of a flat plate solar collector in transient behavior. Energy Conversion and Management, 78, 938–947. doi:http://dx.doi.

org/10.1016/j.enconman.2013.09.044

Jafarkazemi, F., & Ahmadifard, E. (2013). Energetic and exergetic evaluation of flat plate solar collectors. Renewable Energy, 56, 55-63. doi:http://dx.doi.org/10.1016/j.

renene.2012.10.031

10. Jesko, Z. (2008). Classification of solar collectors.

Engineering for Rural Development, 22-27. 11. Kumar, A., & Chandel, S. (2013). Tilt angle optimization to maximize incident solar radiation: A review. Renewable and Sustainable Energy Reviews, 23, 503–513. doi:http://

dx.doi.org/10.1016/j.rser.2013.02.027

12. Larrea, G., & Bayas, H. (2011). Diseño de un sistema solar térmico para la producción de quesos en las comunidades: Chimborazo,

Santa Isabel - Ecuador.

13. Loayza, F. (2012). Diseño e implementación de un

seguidor solar para el control electrónico de

un reflector Scheffler. Tesis título, Lima.

14. Martinez, J. C., Franco, P., & Alonso, R. (2013). Manual termico de energía solar térmica.

Uruguay.

15. Menjura, O. A. M., Tayo, J. L. N., Melo, E. R.

V., Guerrero, A. C., & Bernal, H. R. G. (2011). Ahorro de combustible y energía en horno s usados para la elaboración de panela modificando el diseño de pailas abiertas. Revista fuentes, 9(2).

16. Park, S., Pandey, A., Tyagi, V., & Tyagi, S. (2014). Energy and exergy analysis of typical renewable energy systems. Renewable and Sustainable Energy Reviews, 30, 105–123. doi:http:// dx.doi.org/10.1016/j.rser.2013.09.011

17. Salcedo, C. (2011). Influencia del estudio de la tecnología de vacío en tubos sobre la eficiencia para el calentamiento de agua usando la energía solar. Tesis de grado, Universidad Técnica de Ambato.

18. Skeiker, K. (2009). Optimum tilt angle and orientation for solar collectors in Syria. Revista Energy Conversion and Management, 50, 2439 – 2448. doi:10.1016/j.enconman.2009.05.031

19. Tagliafico, L., Scarpa, F., & De Rosa, M. (2014). Dynamic thermal models and CFD analysis for flat-plate thermal solar collectors – A review. Renewable and Sustainable Energy Reviews, 30, 526–537. doi:http://dx.doi.org/10.1016/j. rser.2013.10.023

20. Taherian, H., Rezania, A., Sadeghi, S., & Ganji, D. (2011). Experimental validation of dynamic simulation of the flat plate collector in a closed thermosyphon solar water heater. Energy Conversion and Management, 52, 301–307. doi:10.1016/j.enconman.2010.06.063

21.Vidal,E.,&Fontalvo,C.(2018).Alternativapara la generación de gas natural sintético a partir de una fuente de energía renovable mediante tecnología “Power to Gas” en Colombia. Revista Fuentes, 16(1), 71-79.

22. Zima, W., & Dziewa, P. (2010). Mathematical modelling of heat transfer in liquid flat- plate solar collector tubes. Archives of Thermodynamics, 31(2), 45-62.