Estudio experimental de la estabilidad y propiedades termofísicas de los nanolubricantes PEG 400-CuO, PEG 400-Grafeno y PEG 400-CuO/Grafeno

Publicado 2021-06-28

Palavras-chave

- polietilenglicol,

- PEG400,

- nanolubricantes biodegradables,

- conductividad térmica,

- viscosidad dinámica

- estabilidad,

- nanofluidos ...Mais

Como Citar

Copyright (c) 2021 Unviersidad Industrial de Santander

Este trabalho está licenciado sob uma licença Creative Commons Attribution 4.0 International License.

Resumo

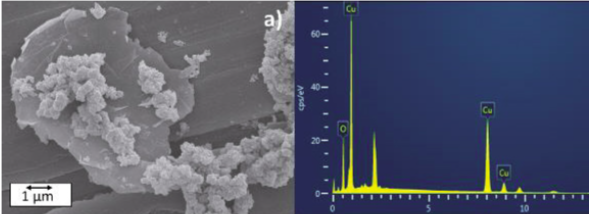

La adición de nanomateriales a los lubricantes convencionales se ha presentado como una alternativa para modificar sus propiedades termofísicas y tribológicas, buscando incrementar su rendimiento. Este estudio presenta los resultados de la evaluación experimental de estabilidad, conductividad térmica y viscosidad dinámica de los nanolubricantes PEG400-CuO, PEG400-Grafeno y PEG400-CuO/Grafeno. Los nanolubricantes se prepararon por el método de dos pasos y se utilizaron dos concentraciones 0.1 y 0.5 % p/p de cada tipo de nanomaterial. Los resultados experimentales mostraron que las dispersiones con menor aglomeración y sedimentación durante el tiempo de evaluación fueron las preparadas con 0.1 % p/p de grafeno. La conductividad térmica de la dispersión PEG400-CuO no presentó diferencias significativas con respecto a la conductividad del PEG400. Sin embargo, la conductividad para las dispersiones PEG400-Grafeno y PEG400-CuO/Grafeno (0.5 % p/p), incrementó hasta un 13.5 % y 5.2 %, respectivamente. La viscosidad dinámica de las dispersiones con una concentración de 0.1 % p/p no presentó cambios significativos con respecto al PEG400, mientras que la viscosidad de la dispersión G-PEG para la concentración de 0.5 % p/p fue superior que la del PEG400 para todas las temperaturas evaluadas.

Downloads

Referências

Alemdar, A., Güngör, N., Ece, O. I., & Atici, O. (2005). The rheological properties and characterization of bentonite dispersions in the presence of non- ionic polymer PEG. Journal of Materials Science, 40(1), 171-177. https://doi.org/10.1007/s10853- 005-5703-4

Azman, N. F., & Samion, S. (2019). Dispersion Stability and Lubrication Mechanism of Nanolubricants: A Review. International Journal of Precision Engineering and Manufacturing - Green Technology, 6(2), 393-414. https://doi. org/10.1007/s40684-019-00080-x

Babar, H., & Ali, H. M. (2019). Towards hybrid nanofluids: Preparation, thermophysical properties, applications, and challenges. In Journal of Molecular Liquids (Vol. 281, pp. 598-633). https://doi.org/10.1016/j.molliq.2019.02.102

Bhaumik, S., Kamaraj, M., & Paleu, V. (2020). Tribological analyses of a new optimized gearbox biodegradable lubricant blended with reduced graphene oxide nanoparticles. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology. https://doi. org/10.1177/1350650120925590

Chen, J., Spear, S. K., Huddleston, J. G., & Rogers, R. D. (2005). Polyethylene glycol and solutions of polyethylene glycol as green reaction media. Green Chemistry, 7(2), 64-82. https://doi.org/10.1039/b413546f

Cortes, V., Sanchez, K., Gonzalez, R., Alcoutlabi, M., & Ortega, J. A. (2020). The performance of SiO2 and TiO2 nanoparticles as lubricant additives in sunflower oil. Lubricants, 8(1). https://doi. org/10.3390/lubricants8010010

Darminesh, S. P., Sidik, N. A. C., Najafi, G., Mamat, R., Ken, T. L., & Asako, Y. (2017). Recent development on biodegradable nanolubricant: A review. International Communications in Heat and Mass Transfer, 86(June), 159-165. https://doi. org/10.1016/j.icheatmasstransfer.2017.05.022

Dhanola, A., & Garg, H. C. (2020a). Influence of different surfactants on the stability and varying concentrations of TiO2 nanoparticles on the rheological properties of canola oil- based nanolubricants. Applied Nanoscience (Switzerland), 0123456789. https://doi. org/10.1007/s13204-020-01467-y

Dhanola, A., & Garg, H. C. (2020b). Materials Today : Proceedings Experimental analysis on stability and rheological behaviour of TiO 2 / canola oil nanolubricants. Materials Today: Proceedings, xxxx. https://doi.org/10.1016/j.matpr.2020.04.245

Geng, Y., Boshra, A. A. A. A. A., Alsagri, A. S., Shahsavar, A., & Talebizadehsardari, P. (2019). Characterization of the nanoparticles , the stability analysis and the evaluation of a new hybrid nano- oil thermal conductivity. Journal of Thermal Analysis and Calorimetry, 0123456789. https:// doi.org/10.1007/s10973-019-08434-y

Gulzar, M., Masjuki, H., Varman, M., Kalam, M., Mufti, R. A., Zulkifli, N., Yunus, R., & Zahid, R. (2015). Improving the AW/EP ability of chemically modified palm oil by adding CuO and MoS2 nanoparticles. Tribology International, 88, 271- 279. https://doi.org/10.1016/j.triboint.2015.03.035

Hemmat Esfe, M., Esfandeh, S., & Rejvani, M. (2018). Modeling of thermal conductivity of MWCNT- SiO2 (30:70%)/EG hybrid nanofluid, sensitivity analyzing and cost performance for industrial applications: An experimental based study. Journal of Thermal Analysis and Calorimetry, 131(2), 1437-1447. https://doi.org/10.1007/s10973-017- 6680-y

Hou, X., Jiang, H., Ali, M. K. A., Liu, H., Su, D., & Tian, Z. (2020). Dispersion behavior assessment of the molybdenum disulfide nanomaterials dispersed into poly alpha olefin. Journal of Molecular Liquids, 311. https://doi.org/10.1016/j. molliq.2020.113303

Hu, Y., Wang, Y., Zeng, Z., Zhao, H., Ge, X., Wang, K., Wang, L., & Xue, Q. (2018). PEGlated graphene as nanoadditive for enhancing the tribological properties of water-based lubricant. Carbon, 137, 41-48. https://doi.org/10.1016/j. carbon.2018.05.009

Huo, M., Wu, H., Xie, H., Zhao, J., Su, G., Jia, F., Li, Z., Lin, F., Li, S., Zhang, H., & Jiang, Z. (2020). Understanding the role of water- based nanolubricants in micro flexible rolling of aluminium. Tribology International, 151(April), 106378. https://doi.org/10.1016/j. triboint.2020.106378

Kim, H. J., & Kim, D. E. (2015). Water lubrication of stainless steel using reduced graphene oxide coating. Scientific Reports, 5(C), 1-13. https://doi. org/10.1038/srep17034

Koshy, C. P., Rajendrakumar, P. K., & Thottackkad, M. V. (2015). Evaluation of the tribological and thermo-physical properties of coconut oil added with MoS2 nanoparticles at elevated temperatures. Wear, 330-331, 288-308. https://doi.org/10.1016/j. wear.2014.12.044

Kotia, A., Rajkhowa, P., Rao, G. S., & Ghosh, S. K. (2018). Thermophysical and tribological properties of nanolubricants : A review.

León, A., Reuquen, P., Garín, C., Segura, R., Vargas, P., Zapata, P., & Orihuela, P. A. (2017). FTIR and raman characterization of TiO2 nanoparticles coated with polyethylene glycol as carrier for 2-methoxyestradiol. In Applied Sciences (Switzerland) (Vol. 7, Issue 1). https://doi. org/10.3390/app7010049

Liñeira, J. M., Guimarey, M. J. G., Comuñas, M. J. P., López, E. R., Amigo, A., & Fernández, J. (2018). Thermophysical and tribological properties of dispersions based on graphene and a trimethylolpropane trioleate oil. Journal of Molecular Liquids, 268, 854-866. https://doi. org/10.1016/j.molliq.2018.07.107

Marcos, M. A., Cabaleiro, D., Guimarey, M. J. G., Comuñas, M. J. P., Fedele, L., Fernández, J., & Lugo, L. (2018). PEG 400-based phase change materials nano-enhanced with functionalized graphene nanoplatelets. Nanomaterials, 8(1). https://doi.org/10.3390/nano8010016

Marcos, M. A., Podolsky, N. E., Cabaleiro, D., Lugo, L., Zakharov, A. O., Postnov, V. N., Charykov, N. A., Ageev, S. V., & Semenov, K. N. (2019). MWCNT in PEG-400 nanofluids for thermal applications: A chemical, physical and thermal approach. Journal of Molecular Liquids, 294, 111616. https://doi. org/10.1016/j.molliq.2019.111616

Mehrali, M., Sadeghinezhad, E., Latibari, S. T., Kazi, S. N., Mehrali, M., Zubir, M. N. B. M., & Metselaar, H. S. C. (2014). Investigation of thermal conductivity and rheological properties of nanofluids containing graphene nanoplatelets. Nanoscale Research Letters, 9(1), 15. https://doi. org/10.1186/1556-276X-9-15

Mello, V. S., Faria, E. A., Alves, S. M., & Scandian, C. (2020). Enhancing Cuo nanolubricant performance using dispersing agents. Tribology International, 150(March), 106338. https://doi.org/10.1016/j. triboint.2020.106338

Nabil, M. F., Azmi, W. H., Hamid, K. A., Zawawi, N. N. M., Priyandoko, G., & Mamat, R. (2017). Thermo- physical properties of hybrid nanofluids and hybrid nanolubricants: A comprehensive review on performance. International Communications in Heat and Mass Transfer, 83(March), 30-39. https:// doi.org/10.1016/j.icheatmasstransfer.2017.03.008

Osama, M., Walvekar, R., Khalid, M., Khaliq, A., Yin, W., Chandra, T., & Manikyam, S. (2018). Physical properties optimization of POME-groundnut- naphthenic based graphene nanolubricant using response surface methodology. Journal of Cleaner Production, 193, 277-289. https://doi. org/10.1016/j.jclepro.2018.05.070

Pownraj, C., & Valan Arasu, A. (2020a). Effect of dispersing single and hybrid nanoparticles on tribological, thermo-physical, and stability characteristics of lubricants: a review. In Journal of Thermal Analysis and Calorimetry (Issue 0123456789). Springer International Publishing. https://doi.org/10.1007/s10973-020-09837-y

Pownraj, C., & Valan Arasu, A. (2020b). Effect of dispersing single and hybrid nanoparticles on tribological, thermo-physical, and stability characteristics of lubricants: a review. In Journal of Thermal Analysis and Calorimetry (Issue 0123456789). Springer International Publishing. https://doi.org/10.1007/s10973-020-09837-y

Rostami, S., Ahmadi Nadooshan, A., & Raisi, A. (2020). The effect of hybrid nano-additive consists of graphene oxide and copper oxide on rheological behavior of a mixture of water and ethylene glycol. Journal of Thermal Analysis and Calorimetry, 139(3), 2353-2364. https://doi.org/10.1007/ s10973-019-08569-y

Sarkar, J., Ghosh, P., & Adil, A. (2015). A review on hybrid nanofluids: Recent research, development and applications. Renewable and Sustainable Energy Reviews, 43, 164-177. https://doi. org/10.1016/j.rser.2014.11.023

Soni, S., & Agarwal, M. (2014). Lubricants from renewable energy sources – a review. Green Chemistry Letters and Reviews, 7(4), 359-382. https://doi.org/10.1080/17518253.2014.959565

Suthar, K., Singh, Y., Surana, A. R., Rajubhai, V. H., & Sharma, A. (2020). Experimental evaluation of the friction and wear of jojoba oil with aluminium oxide (Al2O3) nanoparticles as an additive. Materials Today: Proceedings, 25, 699-703. https://doi.org/10.1016/j.matpr.2019.08.150

Wu, H., Jia, F., Zhao, J., Huang, S., Wang, L., Jiao, S., Huang, H., & Jiang, Z. (2019). Effect of water-based nanolubricant containing nano-TiO 2 on friction and wear behaviour of chrome steel at ambient and elevated temperatures. Wear, 426-427(September 2018), 792-804. https://doi. org/10.1016/j.wear.2018.11.023

Yapici, K., Cakmak, N. K., Ilhan, N., & Uludag, Y. (2014). Rheological characterization of polyethylene glycol based TiO2 nanofluids. Korea Australia Rheology Journal, 26(4), 355-363. https://doi.org/10.1007/s13367-014-0041-1

Yu, W., & Xie, H. (2012). A review on nanofluids: Preparation, stability mechanisms, and applications. Journal of Nanomaterials, 2012. https://doi.org/10.1155/2012/435873

Zhang, C., Zhang, S., & Song, S. (2014). Preparation and Tribological Properties of Surface-Capped Copper Nanoparticle as a Water-Based Lubricant Additive. 25-33. https://doi.org/10.1007/s11249- 014-0304-5